Institute of Digital Materials Science

Main research areas

The following four key areas of materials science and data-driven analysis have been established at the IDM in recent years, thanks to funding measures from externally funded projects and the programme of the Mittelbau:

I: Porous materials

Ia) Medical technology

Highly porous membrane structures made of cellulose nitrate are the main component of medical diagnostic tests (such as COVID tests). In the BMBF project OptiProt - Optimised protein distribution through porosity design, a computer-aided design of open-pored membrane structures was achieved, which optimises fluid transport through capillary forces. In the simulations, complex membrane structures were resolved and the liquid propagation calculated.

Ib) Environmentel technology

As part of the BMWi project PoroSan - Design and modelling of a microbial remediation process for LHKW contamination, consisting of a groundwater circulation well in combination with a newly developed multilevel injection well for nutrient addition, simulation studies were used to determine an optimal process for cleaning contaminated groundwater by dissolving the microstructural porosities of the underlying sand structures. In the Pulsed Water project, flow simulations were used to investigate the introduction of oscillating and/or pulsating three-dimensional flushing flows in groundwater circulation wells. The aim of the flow pulses is to optimise groundwater purification through the mobilisation of pollutants in contaminated groundwater or the introduction of reactants into less permeable areas of the subsurface. In preparation for the application of modelling methods in the prediction of heat transport in geothermal plants, flow simulations of two immiscible fluids were performed in the BMBF project MERID - Multiscale Simulation of Flow Dynamics on the Pore and Reservoir Scale, taking into account the sand particle structures, direction-dependent flow properties for various sediment structures in earth layers were determined and transferred to macroscopic simulations as anisotropic permeability tensors.

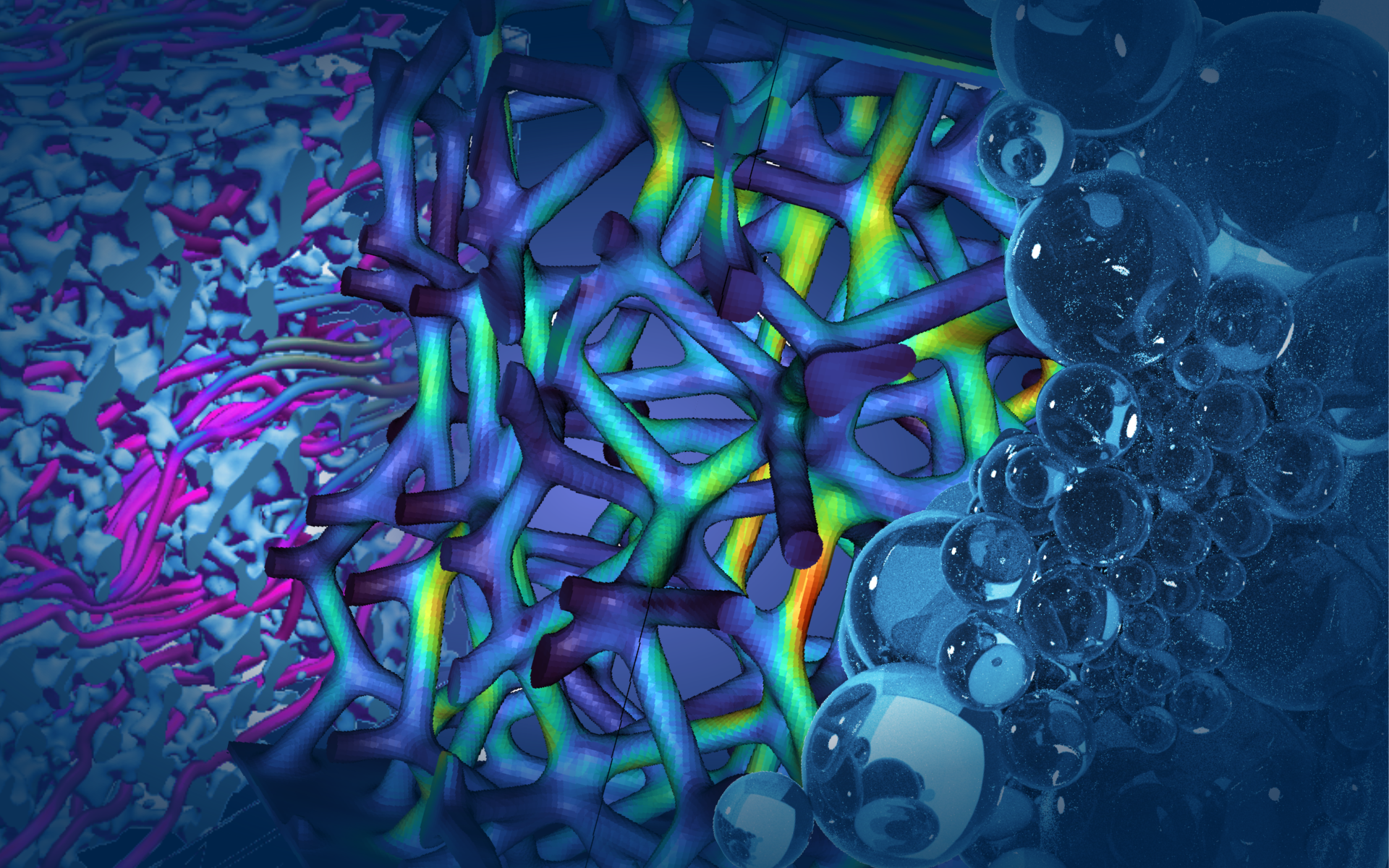

Ic) Lightweight construction: innovative foam structures

Computer-aided design of new types of surface-rich, open-pored metal foams with optimised flow and heating rates was the challenge of the funded BMWi joint project EmiFoam - Development and testing of an inductively heatable instantaneous water heater based on metal foam. In simulation studies, the convective heat transfer during a flow was investigated and new graded metal foam structures were developed and tested as tubular element components during the inductive heating of domestic water. The IDM developed software solutions as the basis for 3D printing of graded foam models and calculated operating characteristics for the pressure loss and the heat transfer coefficient.

The topic of MagicMetal - substitution of toxic materials for thermoelectric applications through the production of magnesium silicide from infiltrated metal foams - promoted the simulation-based development of new hybrid composite materials. Open-pored metal foams were modelled in microstructure simulations and the subsequent infiltration was treated with a specifically adjustable solid-state transformation.

The Centre for Applied Research (ZAFH) - InSeL I and II - Innovative Foam Structures for Efficient Lightweight Construction is a research association of the universities of Pforzheim and Karlsruhe and the KIT, funded by the MWK Baden-Württemberg and the European Regional Development Fund (ERDF). For functionally optimised applications with anisotropic load behaviour, experiments and simulations based on open-cell metal foams are to be used to develop new types of cellular lightweight materials and composites with high inherent stiffness. Research work includes the microstructural characterisation of the foam structures, comprehensive property analyses, topology optimisation under mechanical load and the development of new models to describe the formation of polymer foams.

Restarts and continuations

Restart of the BMBF project MultiPore, from 01.01.2022: Continuation of the cooperation with the industrial partner Sartorius GmbH, for multiscale modelling of the physical processes of liquid propagation and adsorption in diagnostic membranes of lateral flow tests.

Restart of the BMBF project BioSorb - Computer-aided design of flow and adsorption processes in bioreactors, from 01.01.2022. The aim is to develop a validated solution method for the design and development of in situ bioreactors for use in groundwater remediation plants. The simulation models are intended to capture and predict the adsorption of endocrine disruptors.

II: Microstructure-driven material development

As part of a cooperative doctoral programme funded by the MWK Baden-Württemberg, Microstructure Analysis and Process Evaluation, the HKA acted as speaker for a joint doctoral programme with the KIT and the HAW Offenburg . In total, research work in the field of material and process development was successfully supervised by two generations of doctoral students, each with 12 doctoral students. The thematic focus covered the following areas: (i) Analysing the interaction between microstructure and mechanical/flow-mechanical force effects and (ii) Researching the correlations between material properties and process conditions.

A systematic description of the interactions between the morphology, the reaction process and the resulting microstructural and mechanical properties in reactive multilayer systems is the research object of the current DFG-SFB joint project PAK 983/1. The results are to be used to determine the potential of self-propagating transformations in intermetallic reactive systems for applications.

With the project Microstructure simulation of solidification in the weld seam, the IDM is involved in a newly established DFG research group FOR-5134 - Solidification cracks in laser beam welding: high-performance computing for high-performance processes . Using macroscopic process conditions, the influencing variables of microstructural hot crack formation are determined in microstructure simulations. For this purpose, the solidification and segregation behaviour is calculated and the probability of crack formation in metallic weld seams is determined.

In the field of additive manufacturing, the ZIM project PST - Process Control Tool for Additive Manufacturing of the BMWI is also being carried out. The PST to be developed is intended to enable consistent quality in the additive manufacturing of PLA-based components by digitising the printing process and simulating it in advance for each individual printing process. At the IDM, the focus is on modelling the crystallisation process of the melted filament and predicting the effective material properties after the curing process.

Restarts and continuations

Restart of the DFG project NanoBain - Mechanism-based microstructure design of low-carbon Giga-NANOBAIN steels, on 01.07.2022. The aim is to develop low-carbon Giga-NANOBAIN steels that overcome the mechanical compromise to steels using a ‘bottom-up’ microstructure design strategy. The focus of the IDM project part is to optimise the processing steps of heat treatment by modelling chemo-thermo-mechanical, microstructural transformation processes and predicting the resulting morphology and effective mechanical properties.

III: New energy materials

The prediction of the degradation caused by a microstructure change in innovative all-ceramic SOFC fuel cells was analysed in the BMBF joint project KerSOLife100 . The electrochemically induced change in the microstructure was calculated in simulations with three-phase grain structures and optimisation proposals for the electrode microstructure were developed in comparison with the experiment.

The BMBF project WirLebenSOFC - Understanding the interdependencies of ageing mechanisms for predicting the service life of SOFCs was approved as a direct follow-up project. The main objective is to investigate the degradation mechanisms of solid oxide fuel cell (SOFC) systems for reconverting ‘green’ hydrogen, especially that produced in a climate-neutral way, into electricity when operated with H2 or H2-enriched fuel gas and to develop models for predicting their service life. At the IDM, the microstructural ageing processes of SOFC anodes are modelled under operating conditions in order to gain a deeper understanding of the microstructural degradation mechanisms and to pass on the findings to physical simulation methods and ML methods for ageing prediction.

Restarts and continuations

Relaunch of the BMBF project ElChFest - Electro-chemo-mechanical modelling of cerium oxide-based solid oxide electrolysis cells: The overall aim of the project is the model-based optimisation of cerium oxide-based electrolysis cells. Three-dimensional electro-chemo-mechanical modelling will be used to predict the relationships between the chemical expansion of the cerium oxide in the cell's layered composite, the operating parameters and the resulting cracking in the electrolyte. Simulations will be used to determine optimum design parameters for the cell and safe operating fields and enable knowledge-based optimisation of the cell. The focus at IDM is on modelling the formation and propagation of microcracks in the porous polycrystalline electrode microstructures under process conditions.

IV: Research data infrastructure Kadi4Mat and sustainable software development of Pace3D

In collaboration with the University of Erlangen and the KIT, a combination and integration of the two HPC software frameworks waLBerla and Pace3D, as part of the BMBF project SKAMPY - Ultra-Scalable Multiphysics Simulations for Solidification Processes in Metals, created HPC software for complex application-orientated problems in materials science and demonstrated high performance on national high-performance computer systems.

The IDM is involved in the internationally leading Science Data Centre (SDC) MoMaF - Molecular Materials Research , which is funded by the MWK Baden-Württemberg. The work at the IDM integrates representative prototypes for practical data management and practical data workflows for materials science applications into the newly created research data infrastructure Kadi4Mat.

With the project Sustainable Data and Software Management for Research Software for the Simulation of Solidification Cracks in Laser Beam Welding, the IDM is taking on the overarching task of defining common data standards, developing data and software interfaces and implementing data analysis methods for the standardised evaluation of experimental and simulated data with large volumes within the DFG research group FOR-5134 .

The BMWi-funded project ProStroM - Production and structure-optimised metal flow field for bipolar plates: Simulative topology optimisation (SimTop) is also dedicated to the optimisation of fuel cell systems. Through the precise preparation of geometry, material and process control data, the aim is to optimise the topology of the structures through which gas flows by means of phase field simulations of the coupled O2 diffusion and the flow processes.