NanoBain: Mechanism-based microstructure design of low-carbon Giga-NANOBAIN steels

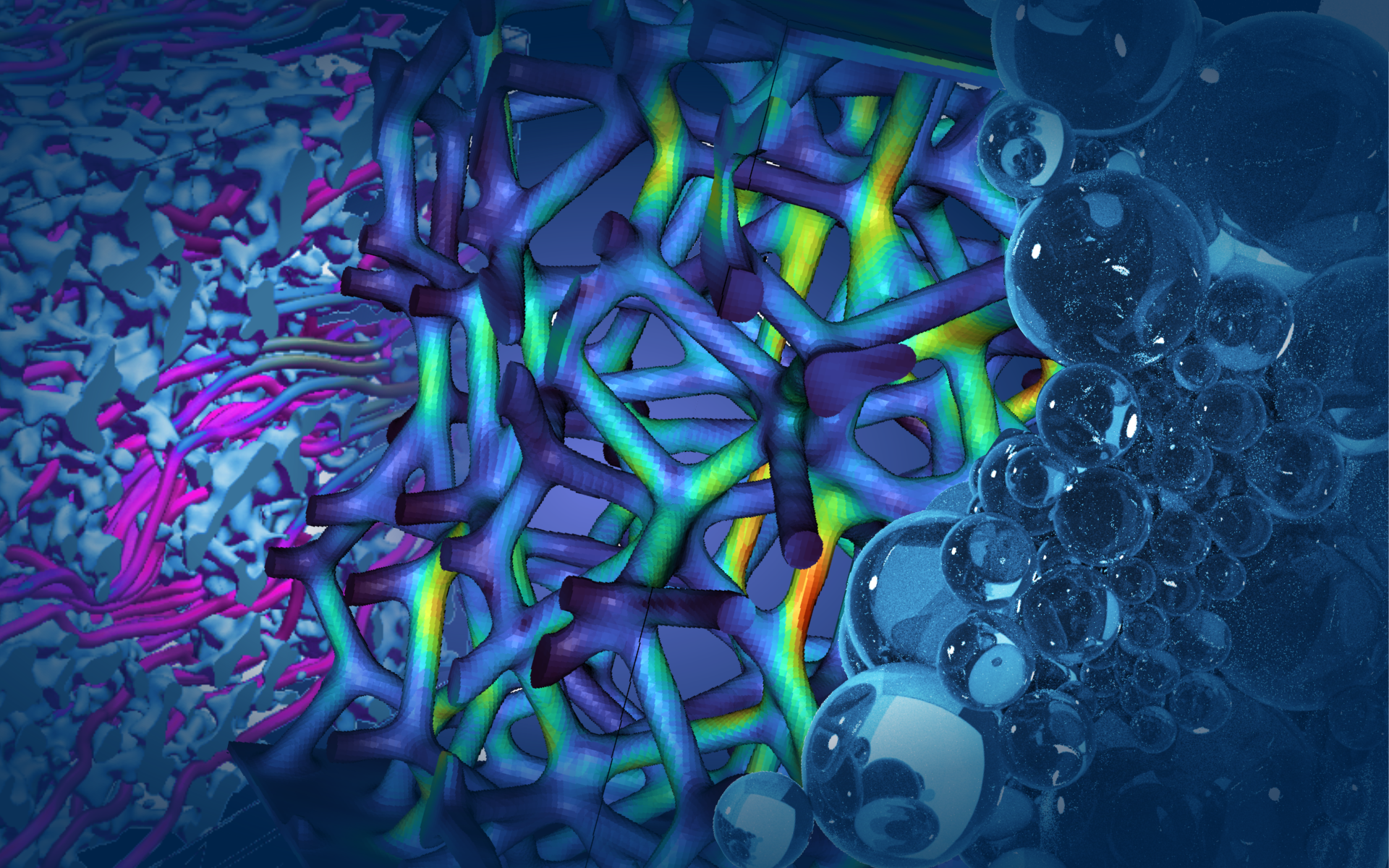

The project deals with the development of low-carbon bainitic steels with high strengths. The desired duplex microstructure of carbide-free, nano-sized bainite and film-like austenite has a high number of interfaces. The strength of so-called nanobain steels is largely determined by the morphology, size and proportion of the bainitic phase. Nanobain steels achieve improved strength, toughness and ductility. With the advantages of low-carbon composition and simple manufacturing process, nanobain steels are expected to contribute to the development of low-cost, environmentally friendly and sustainable manufacturing, for example, the development of sustainable manufacturing of high-performance components in the automotive industry.

To achieve a refinement of the bainitic microstructure with adapted mechanical properties within a low-carbon regime, a chemical frontier concept is proposed and flash austenitization is developed to introduce a chemical frontier into the materials.

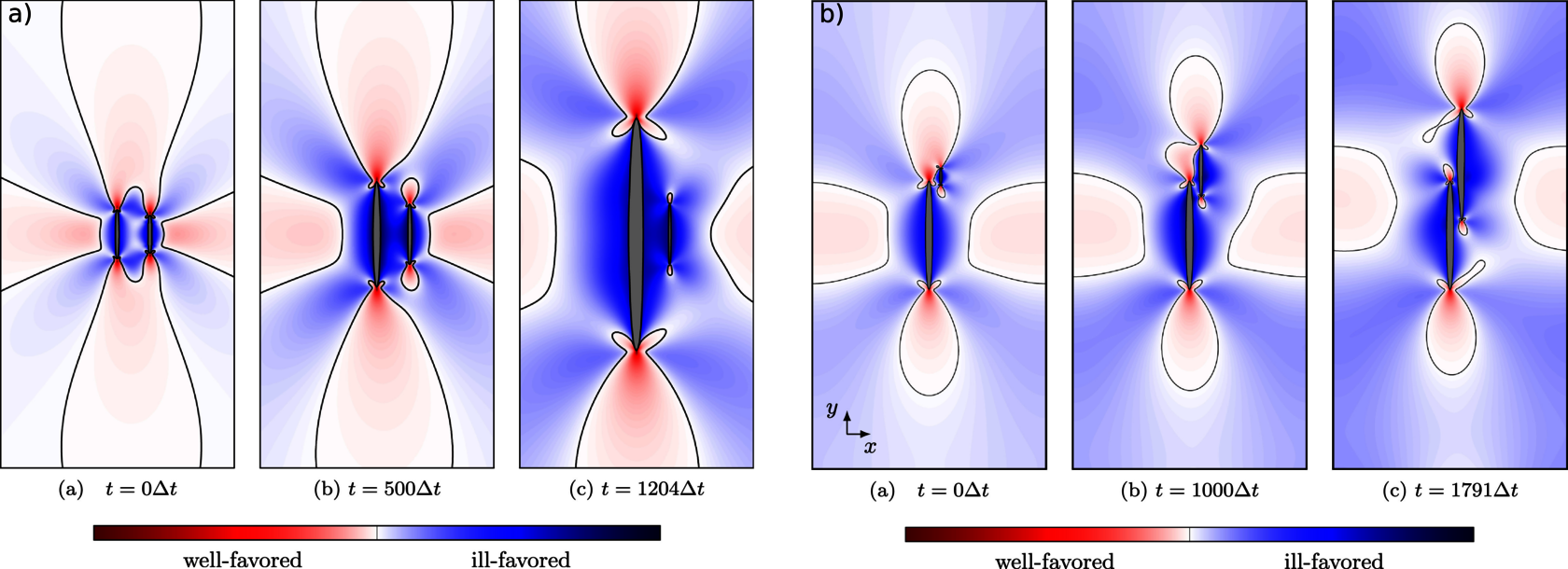

The research focus is on the investigation of the chemical-mechanical coupled effects on bainite nucleation and bainite growth by multiscale characterization and phase field simulation approach:

- University of Kassel (Prof. Dr.-Ing. habil. Wenwen Song): Multiscale characterization using atom probe tomography (APT), synchrotron X-ray diffraction, in-situ TEM

- Karlsruhe University of Applied Sciences (Dr.-Ing. Daniel Schneider): Phase field simulation approach with Pace3D