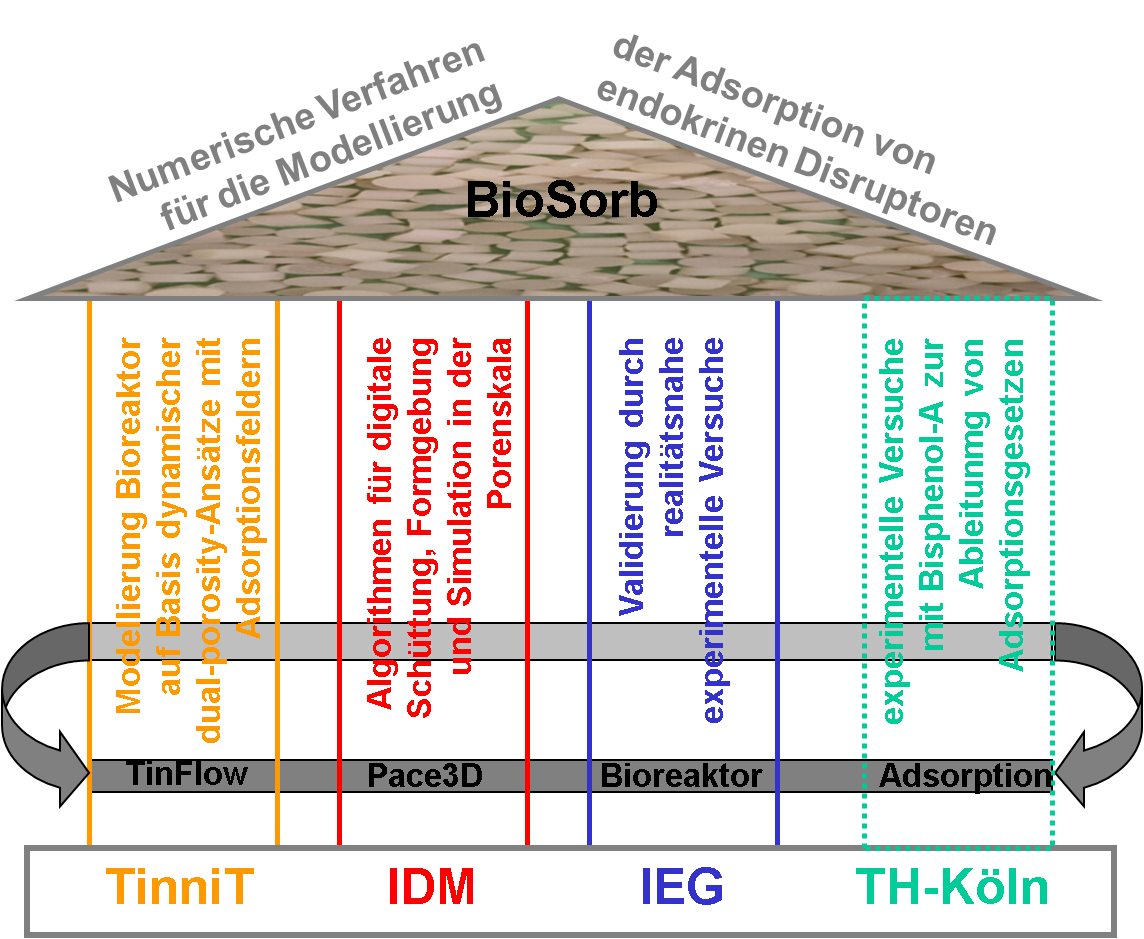

BioSorb: Computer-aided design of flow and adsorption processes in bioreactors

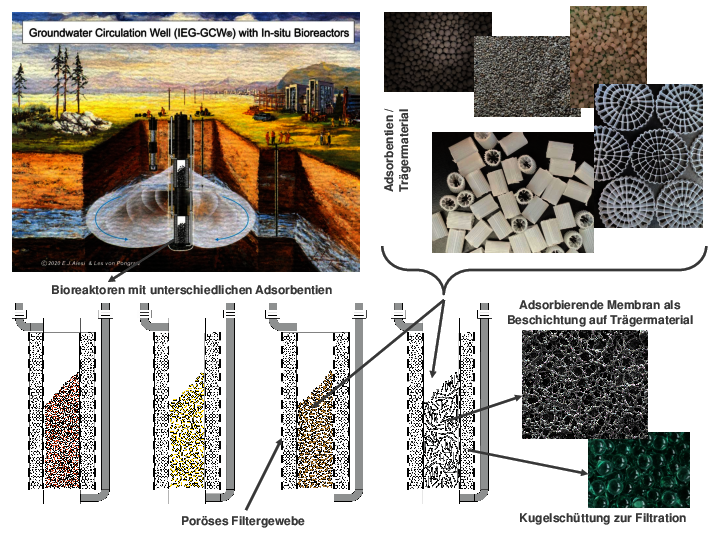

Compared to other topics, the field of activity "protection of water as a resource" is gaining increasing potential due to the challenges of climate change and offers companies challenges and market opportunities in the environmental technology sector. Many studies highlight the need to purify and reuse water at all levels of utilization. Heterogeneously structured aquifers are widespread and pose special requirements for remediation measures in the event of contamination. The pollutants fixed there in small-scale micro- to nanoscale pore structures can only be removed by conventional technologies over very long periods of time. The use of groundwater circulation wells (GCW), which generate a pronounced vertical flow in the subsurface, can significantly improve the mobilization of contaminants in the subsurface. The principle of operation of a GCW and the structure can be seen in the following illustration.

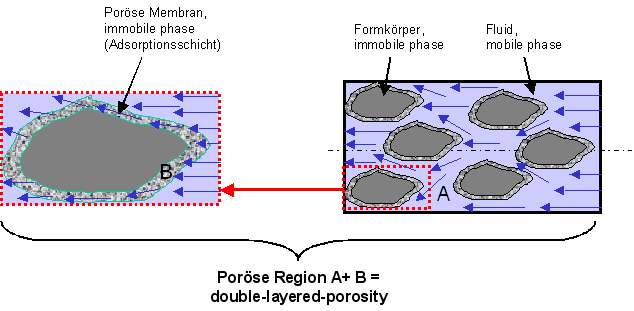

From market development to environmentally friendly and low-energy remediation systems, the combination of GCW with in-situ bioreactors has come into focus as an innovative approach to in-situ groundwater remediation. A bioreactor can contain selected inoculated microorganisms, adsorbents, growth materials or releasable nutrients. Integration into the groundwater circulation process optimizes the biological remediation process used in practice to date. Thanks to the special building technology of the reactors, carrier materials can be conditioned, reactivated or completely replaced. A loop function allows for a secondary cycle that is superimposed on the circulation in the surrounding aquifer. Reagents can be added to this in solid or liquid form without any significant transfer into the aquifer. The direct operation of such reactors, under the natural conditions of the aquifer, can also be expected to result in the detachment and transport of microorganisms or other colloidal particles, e.g. in pulsed operation, as well as the transfer of catabolic end products or enzymes into the surrounding porous space, thereby expanding it into a larger-scale reaction space. The following figure shows granules with a porous coating around which a liquid substance flows. The areas between the grains represent the interior of the global porosity. The coating of the bodies represents a much finer local porosity.

Integrating these bioreactors into the GCW promises a further improvement in pollutant degradation, as this allows the "treatment zone" to be thermally linked to the aquifer via filtration elements. This process represents a promising approach. However, an essential condition for successful application is an efficient degradation or adsorption rate of the mobilized pollutant in an in-situ bioreactor. A bioreactor usually consists of a porous filter fabric, the associated connecting pipes and the actual reactor core. It can consist of a bed of adsorbents (e.g. coated carrier bodies or solid activated carbon material). For remediation methods based on GCW, predicting the degradation rate during the flow through such bioreactors is a crucial prerequisite, as multiple superimposed physical effects, such as a different flow velocity, a variation of the bed caused by pulsation, etc., must be taken into account when creating a model.