Sustainable Off-grid solutions for Pharmacies and Hospitals in Africa

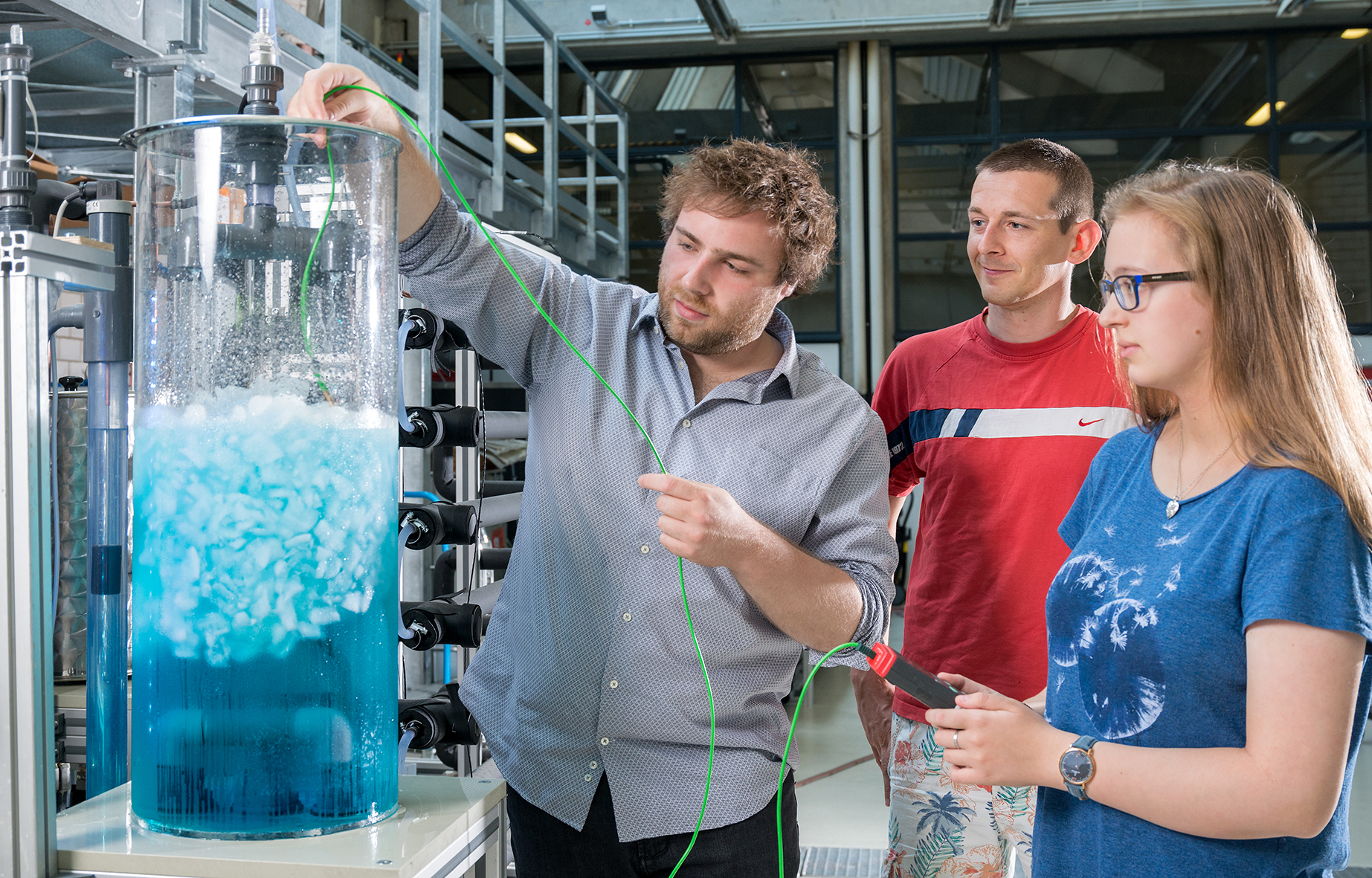

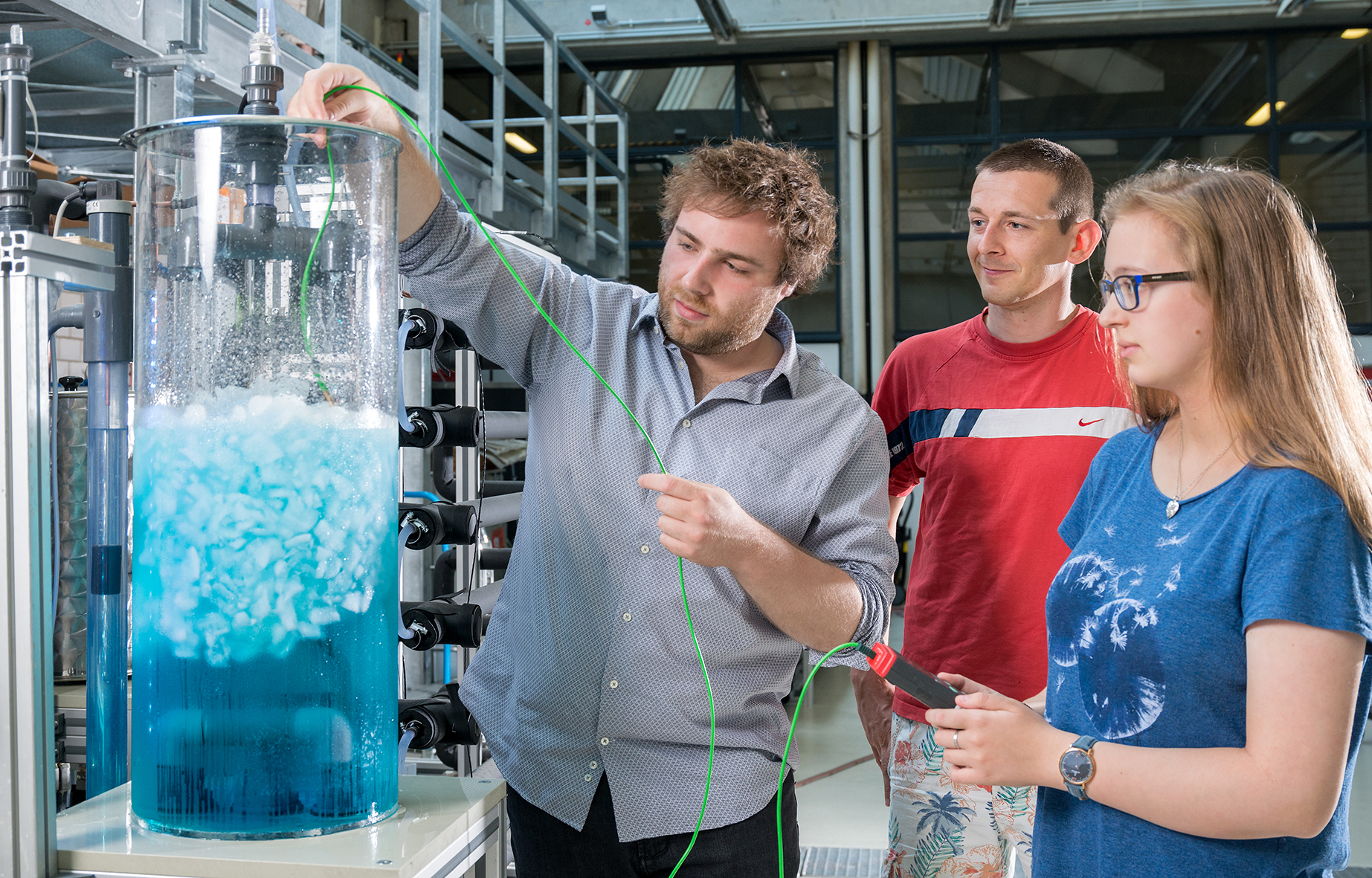

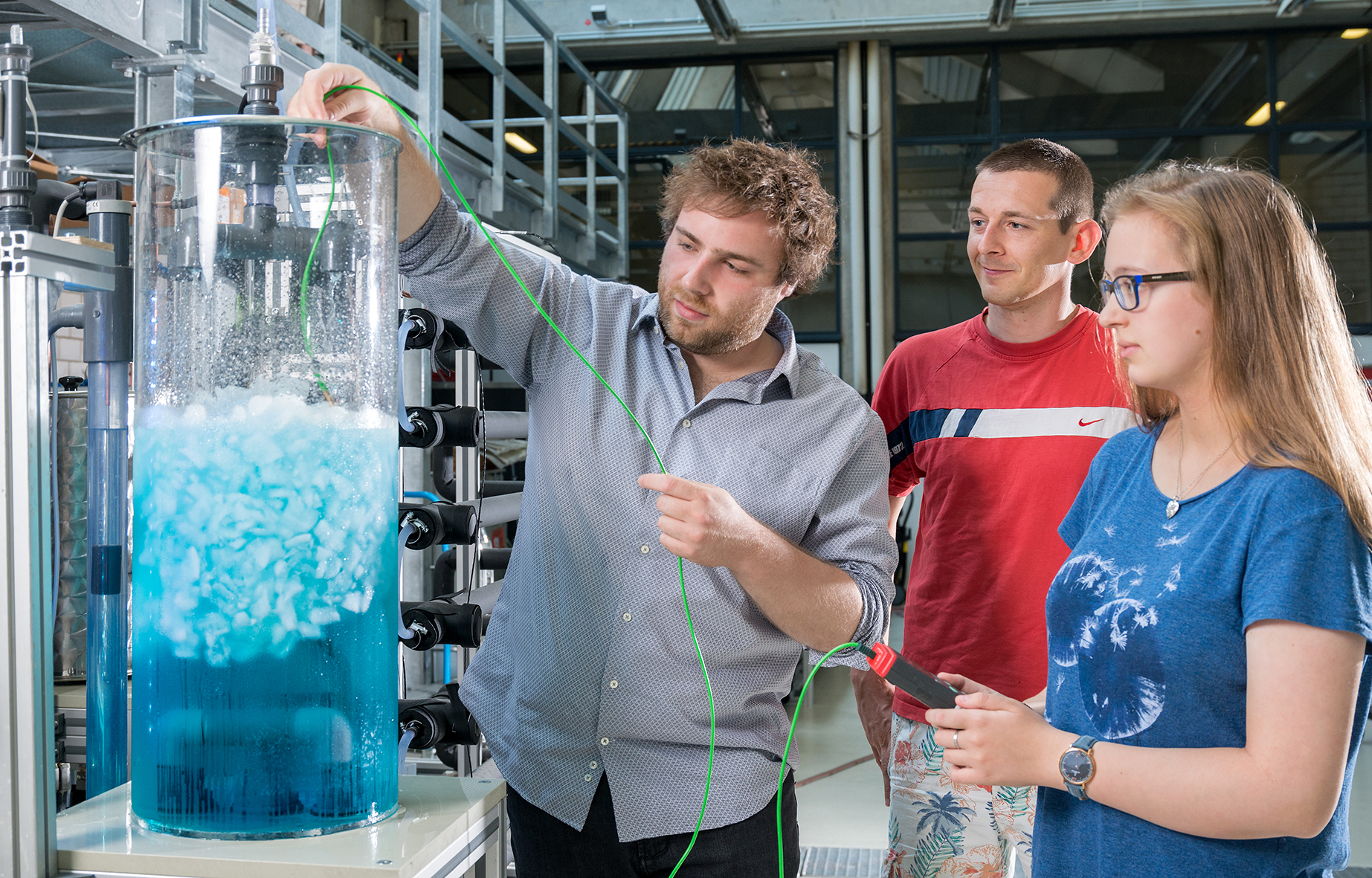

The EU project “SophiA”, which started in October, aims at developing two solar-powered 40-foot container systems for remote hospitals in Africa. A first container will provide reliable cooling and storage of vaccinations, medicines and blood plasma at low cost. The cooling requirement at three different temperature levels (+5, -30 and -70 ° C) is reached efficiently and with climate-friendly natural refrigerants. In addition to the refrigerated container, a second container ensures a secure power supply and supplies the hospital with clean drinking water and hot water as well as steam for sterilization.

more