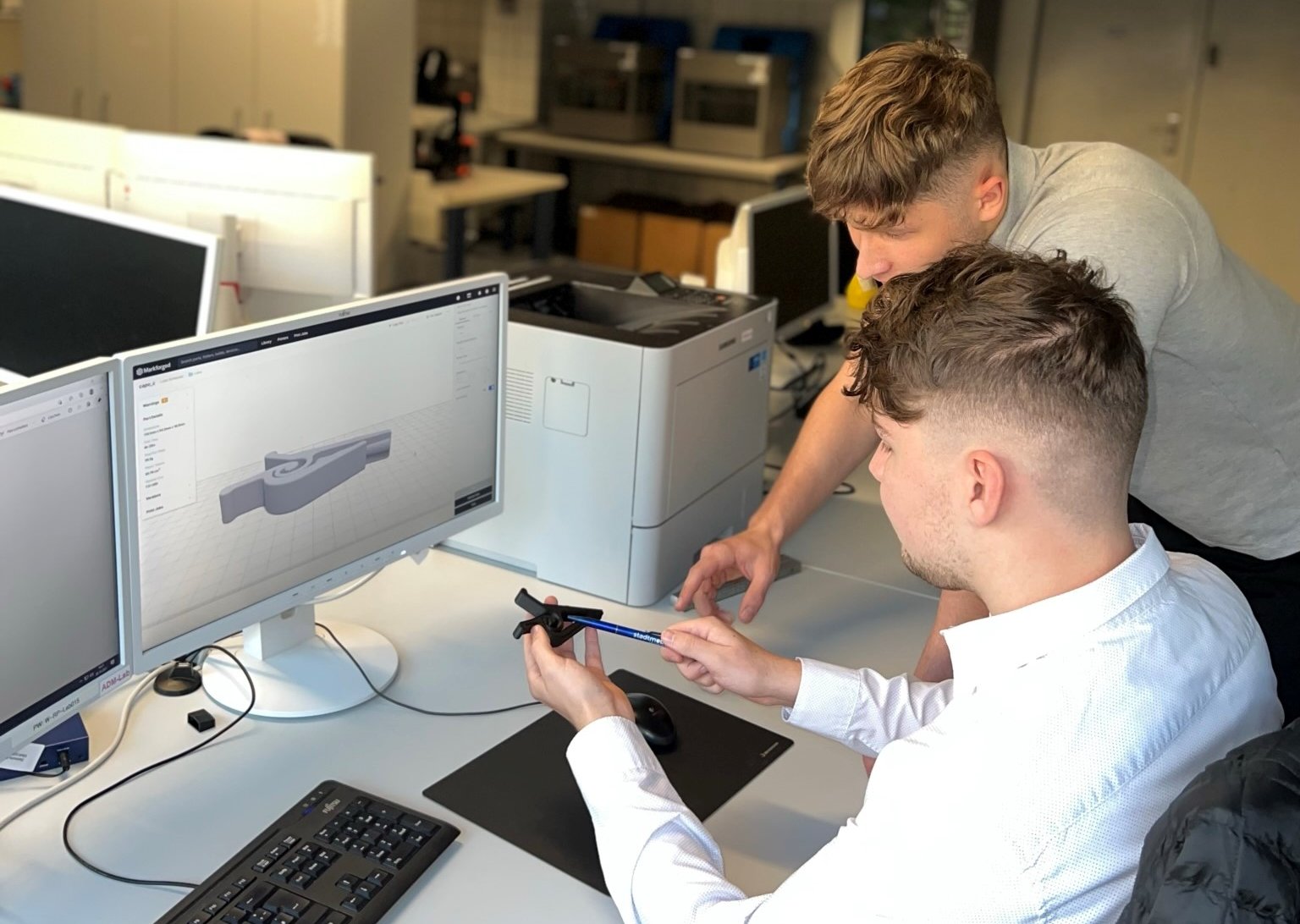

Additive Design and Manufacturing Lab

At the intersection of mechanics, electronics, materials, robotics, and computer science, students bring innovative ideas to life around 3D printing in areas such as:

- Process technology, with a focus on extrusion processes and stereolithography

- Component design and layout

- Profitability analyses and business models

The ADM Lab has a growing pool of 3D printers, some of which are adapted, optimized, or modified in-house. In various projects, students utilize the lab for the rapid production of specific functional components. Whether for their own theses or external projects, the ADM Lab conducts and supports diverse research activities, primarily focused on additive manufacturing.