PIPE

In PIPE, we are researching methods that enable robot systems to adapt to new tasks in production environments. A representation learning module is being developed to enable learning contact models by incorporating prior knowledge of geometry, materials, and ODE. The estimated contact model can then be used to automatically design force control parameters for joining applications using traditional controller synthesis methods .

ADeMoRos

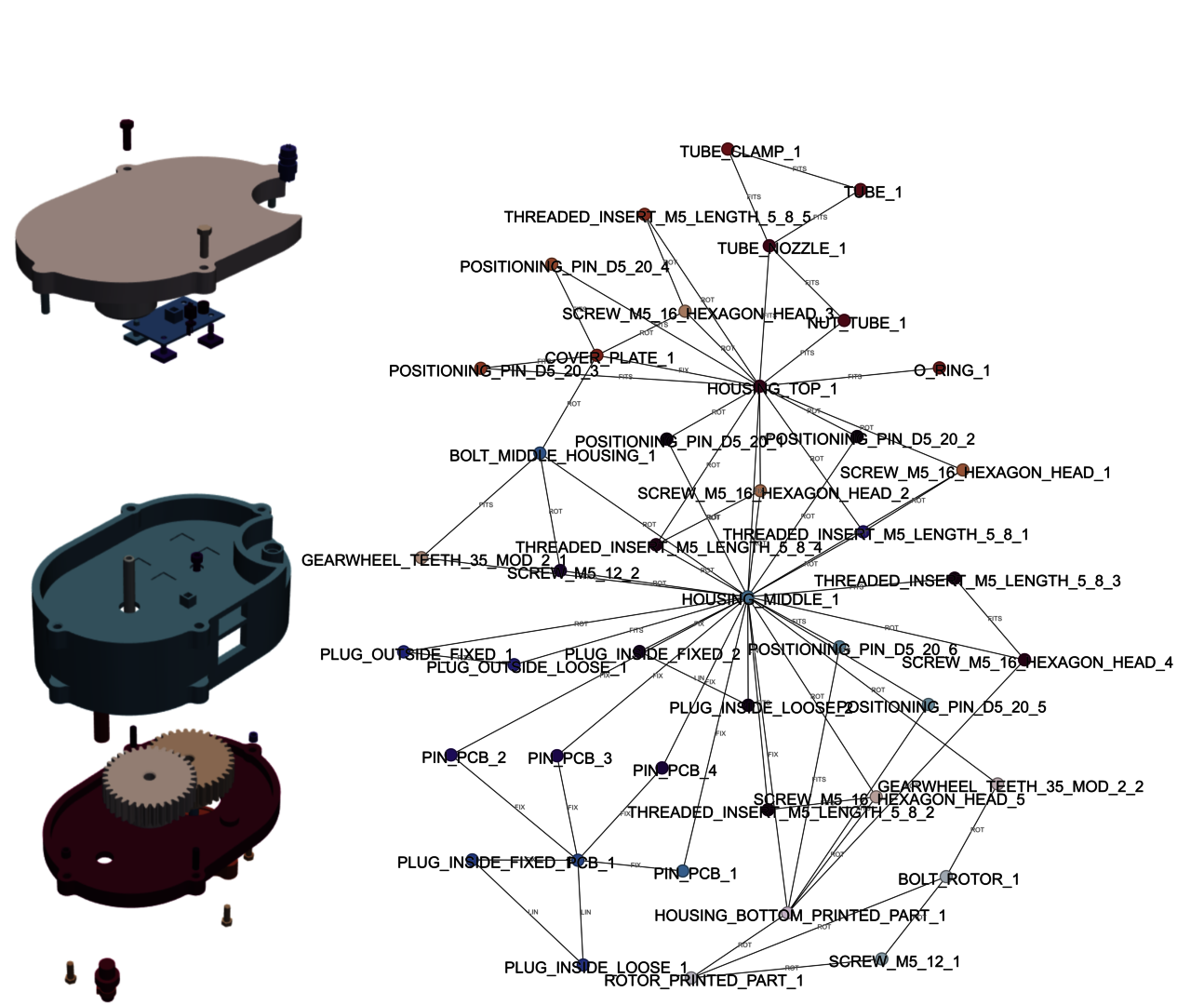

The project aims to develop intelligent software services that enable robot systems to independently plan and execute assembly and disassembly processes based on CAD and environmental data. Given the increasing demand for resource efficiency and automation, the aim is to create a consistent, autonomous solution - without manual programming. For this, innovative algorithms are being developed that combine symbolic AI processes with data-driven methods: While symbolic approaches enable transparency and physical model integration, data-based methods reduce the complexity of difficult tasks. The generated processes are automatically transferred to robot programs and integrated into a modular software architecture. The result is a flexible system that enables autonomous, cooperative robot interactions for assembly and disassembly processes.

iTENDO

The iTENDO project is researching innovative methods for processing vibration data in machining production. The aim is to reliably predict key process conditions such as workpiece quality, tool wear or chattering.

Particular emphasis is placed on the industrial applicability of the technologies developed. In cooperation with the company SCHUNK, the intelligent tool holder iTENDO is used for this purpose. This sensor system enables 1D acceleration data to be recorded directly on the tool in a particularly process-oriented and non-invasive manner. This means that existing machine tools can be easily retrofitted and the technologies developed can be tested in practice.

One focus is on data-based condition prediction using modern signal processing and AI. Among other things, a combination of Short-Time Fourier Transformation (STFT), automatic feature extraction via a transformer-inspired CNN architecture and an LSTM model for classifying process states are used.

Learn more

ISASDeMoRo

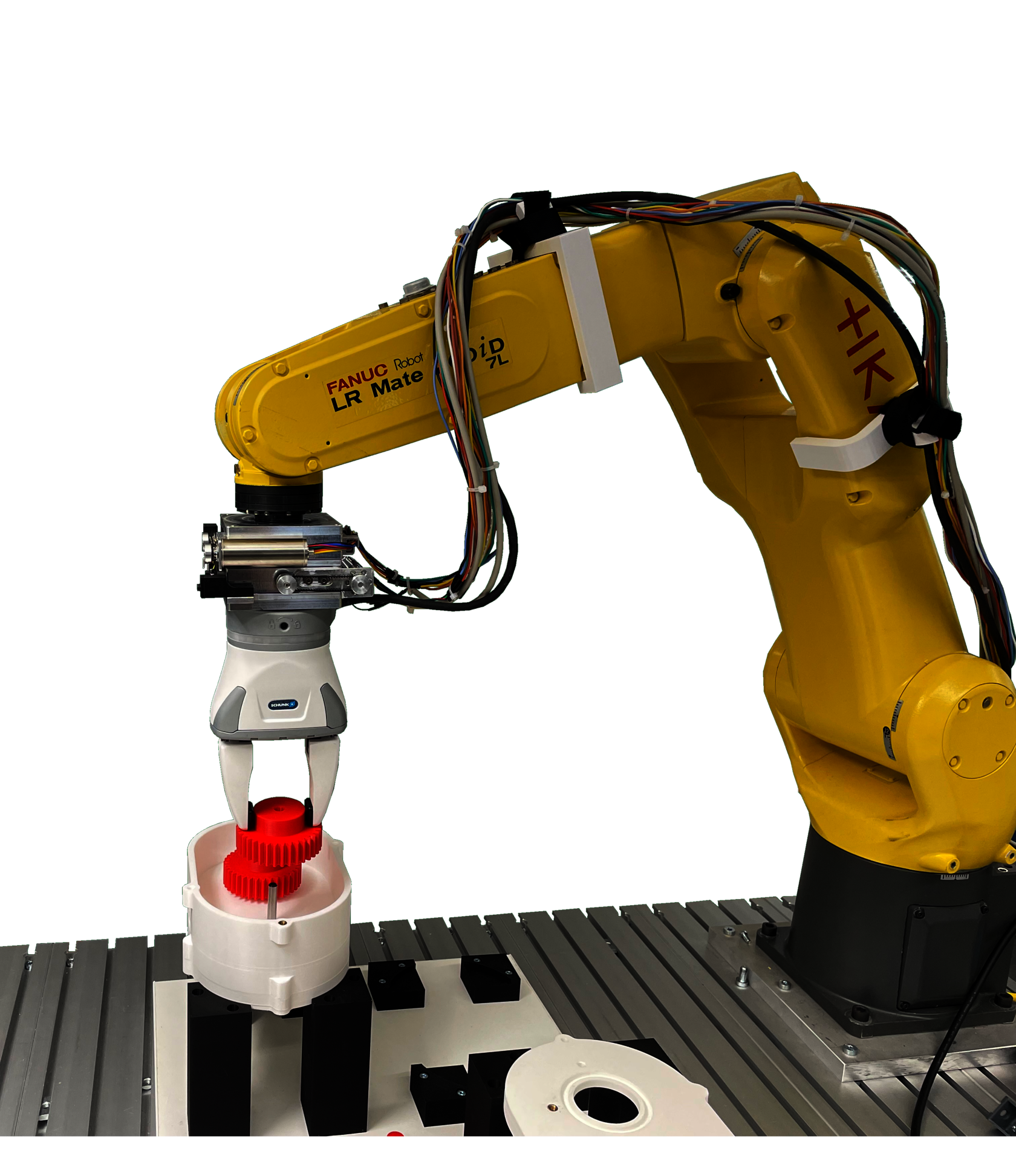

The ISASDeMoRo project is researching innovative autonomous technologies that enable robotic systems to independently perform assembly and disassembly operations. For this purpose, a sensitive sensor-actuator system is being developed which makes it possible to record process variables such as forces and torques as well as camera data, to fuse them and to exert highly dynamic control effects on the sensor-actuator system and the robot. Representation learning is used to model various assembly operations in a generalized way so that the individual capabilities can be transferred to various existing and new robot systems and processes on a modular basis. The process is set up using symbolic instructions, so that no expert knowledge is required and the time-consuming and cost-intensive part of automation is virtually eliminated. The combination of high process dynamics and generalization through representation learning, coupled with simple parameterization of the process, could overcome the current obstacles for a economical use of robot systems in assembly and disassembly and thus initiate a competitive advantage in production technology through autonomous robotics.

Learn more

KIDWAP

The increasing complexity of modern vehicles with up to 180 control units presents the automotive industry with considerable challenges in terms of digital value creation. Processes such as ECU flashing, individual configuration and vehicle commissioning require precise consideration of complex dependencies, sequences and boundary conditions. Traditional, manual approaches to process modeling and quality assurance are reaching their limits with the growing number of variants and increasing production complexity. The project is based on a three-stage, integrated methodology that systematically uses artificial intelligence to analyze and optimize digital value creation in automotive production. This methodology combines data-driven process modeling, generative AI technologies and intelligent anomaly detection into a coherent solution approach.

Learn more

MERLIN

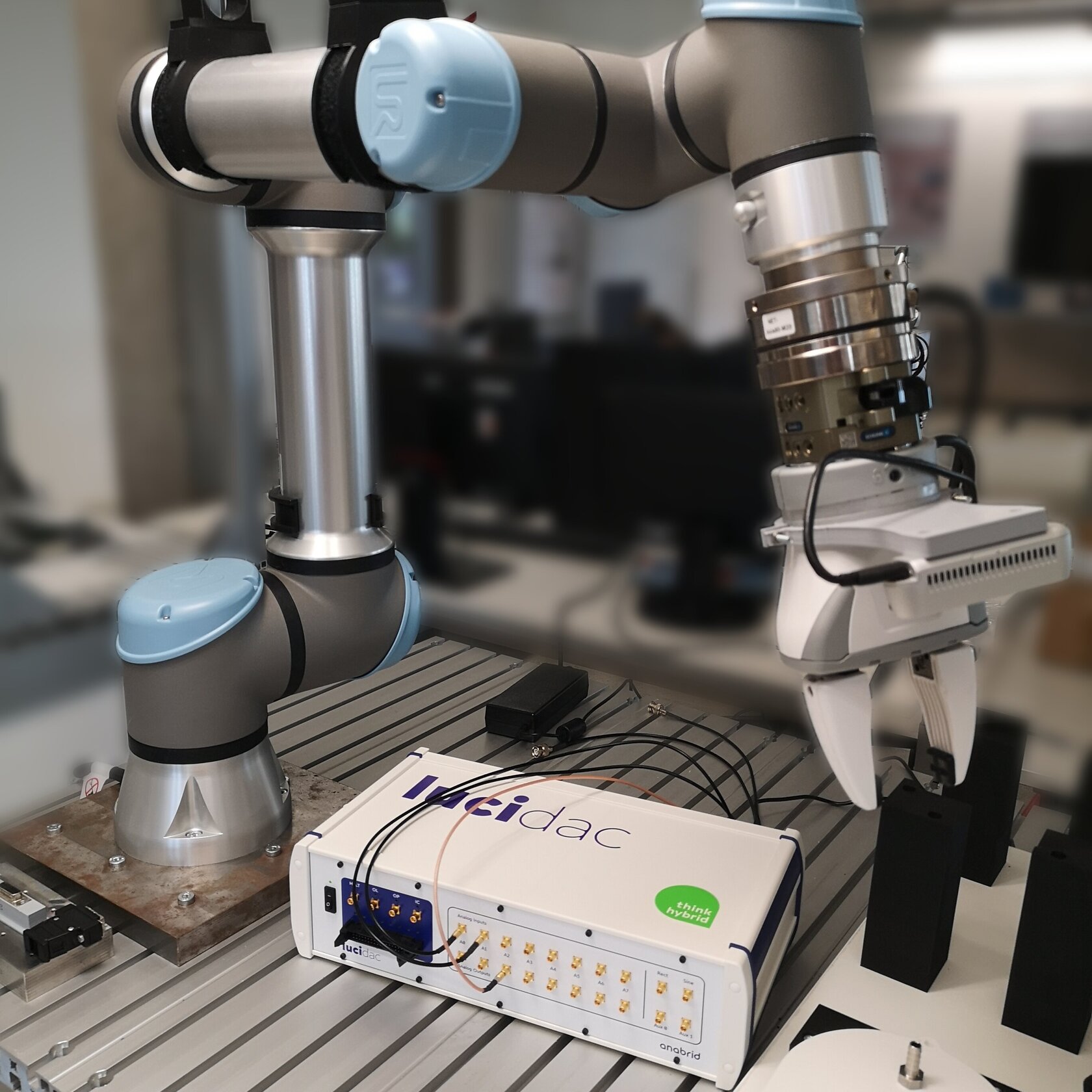

Current machine learning methods use increasingly large models, which require larger computing capacities and greatly increase training and inference time, as well as energy requirements. However, these deficits can be mitigated by employing modern analog computer architectures.

MERLIN explores the potential of analog computers in robotics and machine learning. In addition to implementing classic control algorithms, artificial neural networks are implemented using analog technology.

Learn more