Motivation

As "Industry 4.0" progresses, the demands and expectations regarding the customizability of products are also increasing. As product requirements increase, so does the required complexity of production lines. Adaptive manufacturing processes require the system to be able to react dynamically to changing process parameters. These include changes to components or their positioning. To meet these requirements, machine learning concepts are increasingly being integrated into production systems. Particularly in the context of sensor-supported work steps, getting started is challenging due to the high level of complexity and knowledge required. Complete solutions are already available on the market in the field of sensor technology and intelligent robotics. However, these models have limited dynamics, especially when processing visual signals, which leads to increased process time. In this context, the use of analog computing technology offers clear advantages: the differential equations on which the respective algorithms are based can be simulated using electrical circuits and thus calculated in a way that saves energy and time. Previous analog computers were severely limited by their low reconfiguration capability and flexibility. These disadvantages are now to be compensated for by means of new hybrid analog-digital computers and the advantages thus gained are to be used in the context of robotics and machine learning.

Overall goal

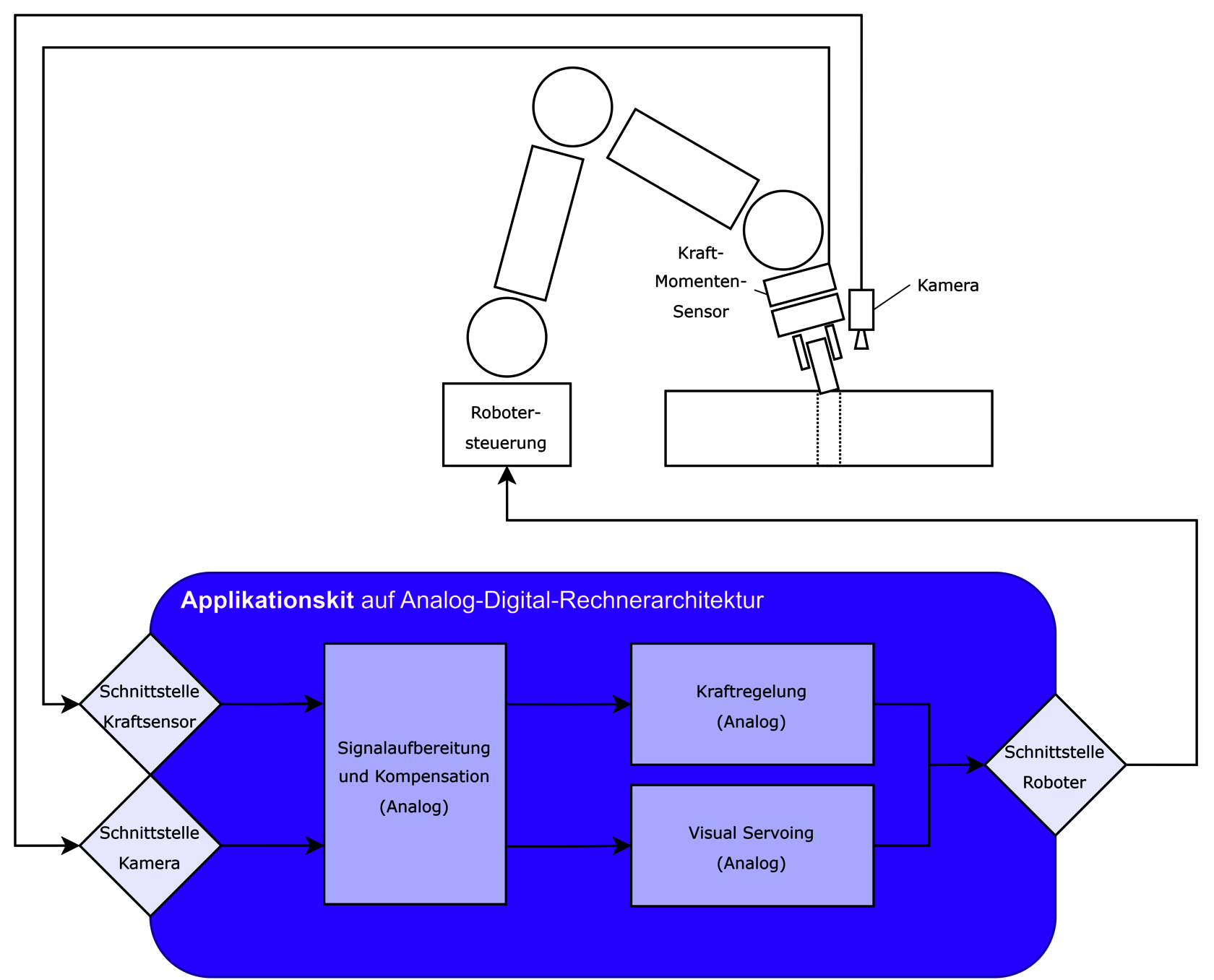

The aim of the research project is to develop control and regulation methods based on an analog computer for the highly dynamic control of robots using exteroceptive sensor technology. A holistic application kit for robot systems is to be developed, which includes the software for the control and regulation methods that can be deployed on an analog-digital computer, which is adapted with the respective interfaces so that both sensors and robot control can be connected to it. This holistic approach can significantly increase the dynamics of execution in particular, which is still one of the main obstacles to the spread of robot-guided disassembly and assembly applications.

Methodology

To control the robot system, multiple controller structures are implemented as differential equation systems and implemented on the software side. In addition to existing classical approaches such as impedance or admittance control, machine learning approaches such as convolutional neural networks are also transferred to the analog domain. The implementation as an electrical circuit enables a significant reduction in inference time, especially when using visual control, which can increase the dynamics of the overall system. Through the direct use of continuous sensor signals and the output of continuous control signals, control problems that were previously regarded as discrete tasks can be calculated and executed with increased accuracy and a low phase shift.

Project funding

The MERLIN project is funded by the Federal Ministry for Economic Affairs and Energy as part of the Central Innovation Program for SMEs (ZIM).