Industrial Internet of Things

Increasing digitalisation is leading to a gigantic transformation within society and industry. We communicate with each other across borders using a wide variety of social platforms, mailing services, etc.. Digital platforms for video conferencing have also become indispensable. In the process, we take on the roles of "producers" and "consumers" of important information, which we consume ourselves or pass on to others in order to be as "up-to-date" as possible and really live up to the popular term "Internet of Things". The internet thus holistically promotes social, but also informative networking. Similarly, Industry 4.0 is leading to a high degree of networking within industry. In addition to the progressive detachment from conventional wire technology, industrial systems such as plants and their subcomponents are being networked into systems of systems. These communicate across miles... production takes place across locations and the systems are becoming increasingly intelligent. Still wired or already networked?

More "mobility", sustainability and safety of industrial systems through high-level digital networking as well as intelligent functions

Mobility and industrial plants - these two terms may not seem to go together at first glance. Overarchingly, it is about "digitalising" production processes and making them faster and more effective.

E-commerce, for example, has a positive influence on consumer behaviour. Through online trade, the range of products is "spread out" in front of the users on the web and they want to get their desired product "quickly". At the same time, individualism is the order of the day. Desired products now include more details and more skills. This leads to one conclusion: more individual products and individual service through "better" production processes, facilities and equipment.

- In the age of digitalisation, "getting better" means pushing the use of real-time communication - think also of 5G. Speed, e.g. within a complex production chain, inevitably leads to "fast desired products", because every delay in sum means a slowdown.

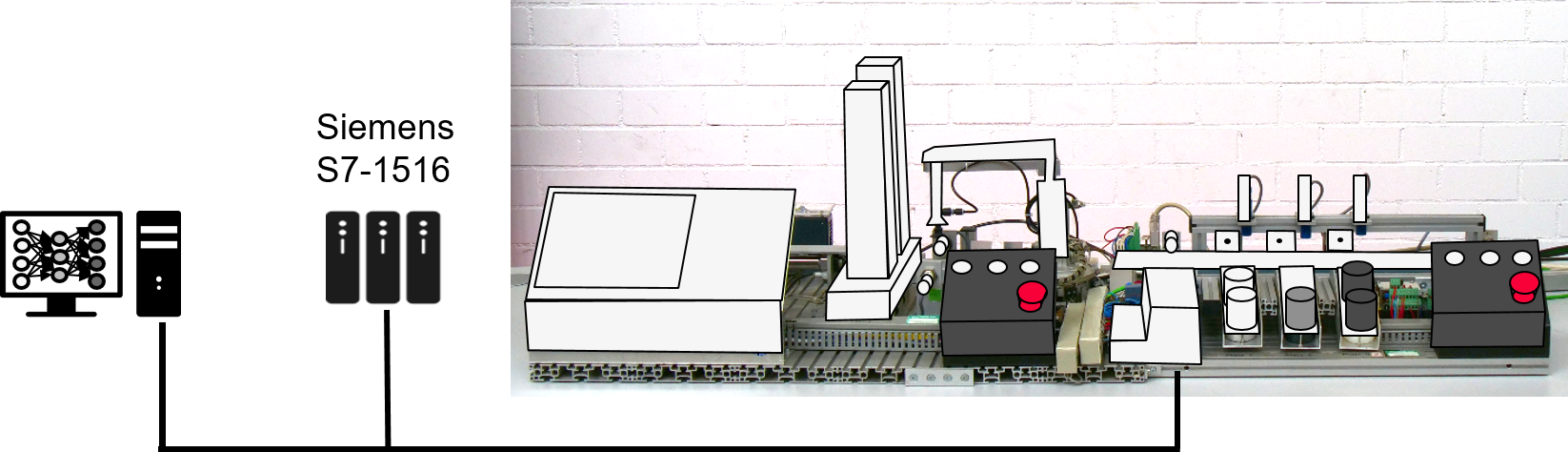

- The development of digital twins, a virtual image of e.g. the plant with its control units, fieldbus systems, interfaces as well as sensors and actuators, allows the conception and analysis of application functions for the plant. The modelling also helps developers to integrate safety concepts.

- The question of individualism and more functionality can be answered with the help of Artificial Intelligence (AI) and Machine Learning. The more intelligent a system is, the better it can adapt to and process different initial situations and tasks. AI methods are also in demand for image recognition. Conversely, with complex neural networks for AI, the topic of speed of data transmission is again an important aspect.

- The aspect of secure data transmission through encryption procedures as well as data protection through pseudonymisation and anonymisation is also addressed.

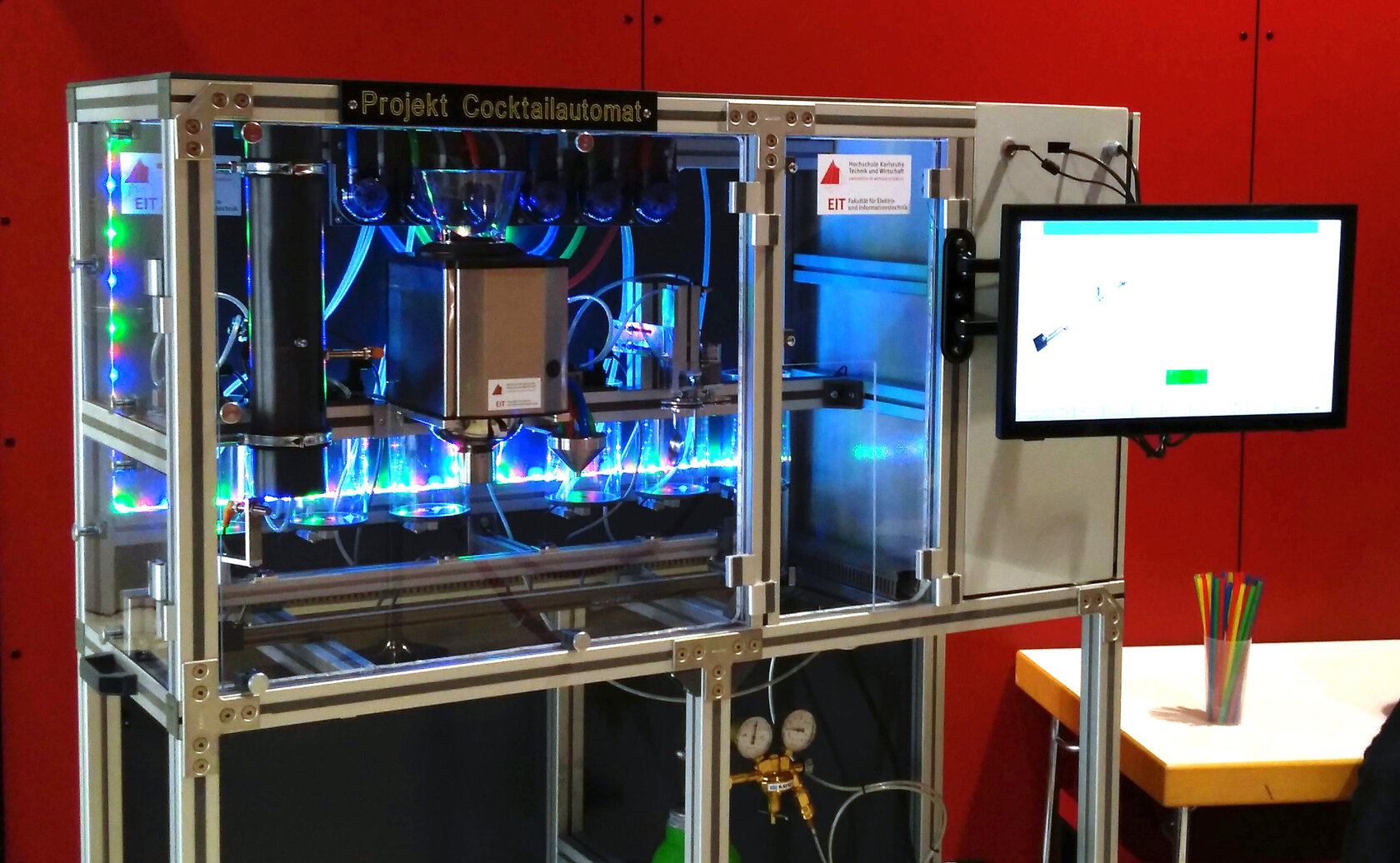

IEEM's research focuses on the areas mentioned above and next to it and strives for cooperation with science and industry. Students can also advance the development of the Industrial Internet of Things with their final theses and projects.

Key data

Karlsruhe

Institute of Energy Efficient Mobility (IEEM)

Moltkestr. 30

76133 Karlsruhe

Post >

Institute of Energy Efficient Mobility (IEEM)

Postfach 2440

76012 Karlsruhe