CaFroPeSens

New electrochemical system for phosphate detection

As part of the BMBF joint project "CaFroPeSens", a project consortium from research and industry revolutionizes phosphate detection

Motivation

The increasing input of phosphate via fertilizers or industrial processes leads to excessive nutrient enrichment of water bodies and to a significant deterioration of water quality. Current detection methods use a standardized wet chemical method based on ISO 6878:2004. Its disadvantage: all reactants must be carried along and added at the right time in the right concentration to enable a correct quantification. In addition, the maintenance of wet-chemical systems is costly.

"CaFroPeSens" presents a solution for this issue.

Contact

Project manager

Prof. Dr. rer. nat. Karsten Pinkwart

Project goal

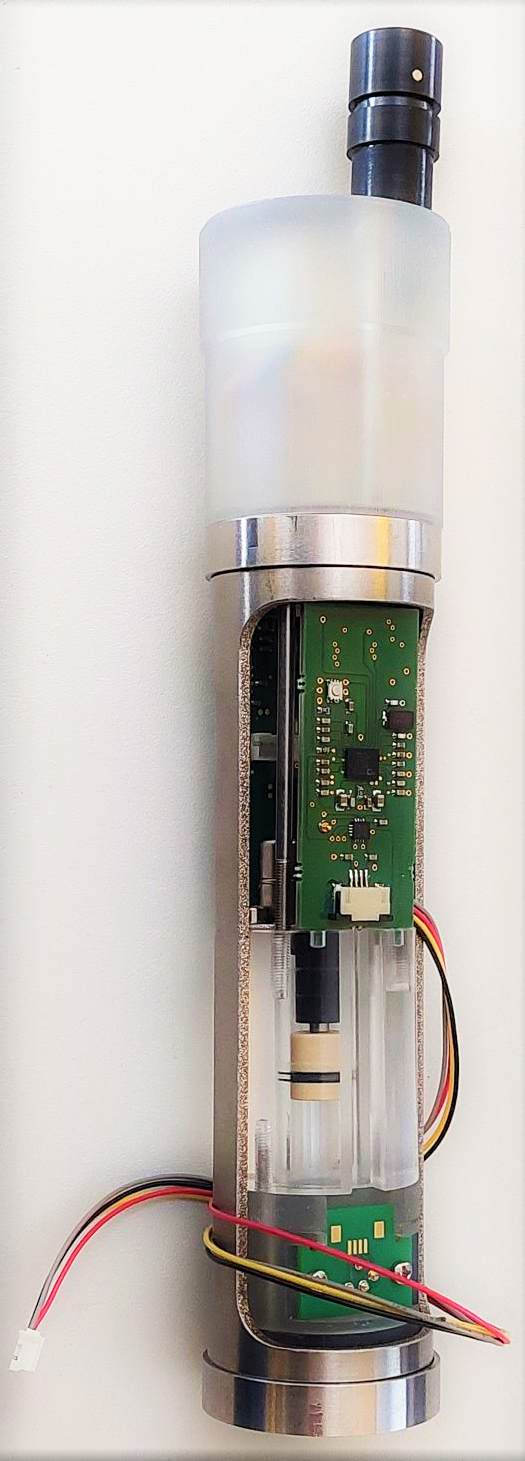

The aim of the CaFroPeSens project is to develop an electrochemically based sensor which can be integrated into a multi-parameter probe. The main objective is the design of a "smart sensor": the autonomously operating probe is combined with different sensors such as a temperature, pH or conductivity. Thus, it can automatically record and transmit all measured values.

The project, which started in 2019, represents the high requirements of a sensor development. To guarantee the functionality of a sensor system, all individual modules must interact perfectly with each other.

The beginning of a measurement chain is always the measurement process itself. The electrochemical principle used is analogous to ISO 6878:2004 but substitutes individual steps. The complex reaction of phosphate and molybdate to form a phosphomolybdate complex (PMC) remains untouched. Instead of dosing, the molybdate is generated in-situ via oxidation of a molybdenum electrode.

Methods

The oxidation mechanism was examined in detail. Using complex electrochemical methods such as linear sweep voltammetry (LSV), basic mechanisms of molybdenum oxidation in aqueous matrix were researched. By use of alternating current (AC) based analytical methods - electro-impedance spectroscopy (EIS) - the layer development during oxidation was investigated. Also, changes in the analyte itself were methodically elucidated by the research partners HKA / Fraunhofer ICT. The complex reaction was evaluated by means of in-situ Raman spectroscopy in a wide range of electrolyte conditions (e.g. varying pH value). An optimal operating point for the oxidation process was found. The spatial and temporal distribution of the molybdate reagent was visualized by electrochemical scanning microscopy (SECM). The amount of molybdate generated was determined by quantitative methods such as optical emission spectroscopy (ICP-OES) and UV-VIS spectroscopy.

Its second difference is the detection mechanism. Instead of determining the phosphate load by optical methods using wet chemical reduction, the sensor uses a voltametric analysis method. The complex is reduced electrochemically, which eliminates the need for dosing. The current signal is indicative for the present phosphate load. Thanks to funding from the BMBF, this novel method was investigated and implemented. The measuring principle, which is based on a classic three-electrode set-up, was extremely miniaturized.

Project findings

Innovative constructive solutions were found to integrate all necessary components in a single rod measuring below 3 cm diameter. In contrast to previous research approaches, the applied sensor system was designed directly for use in aquatic and industrial environments. Considerations such as robustness, low maintenance and ease of use were driving factors during development.

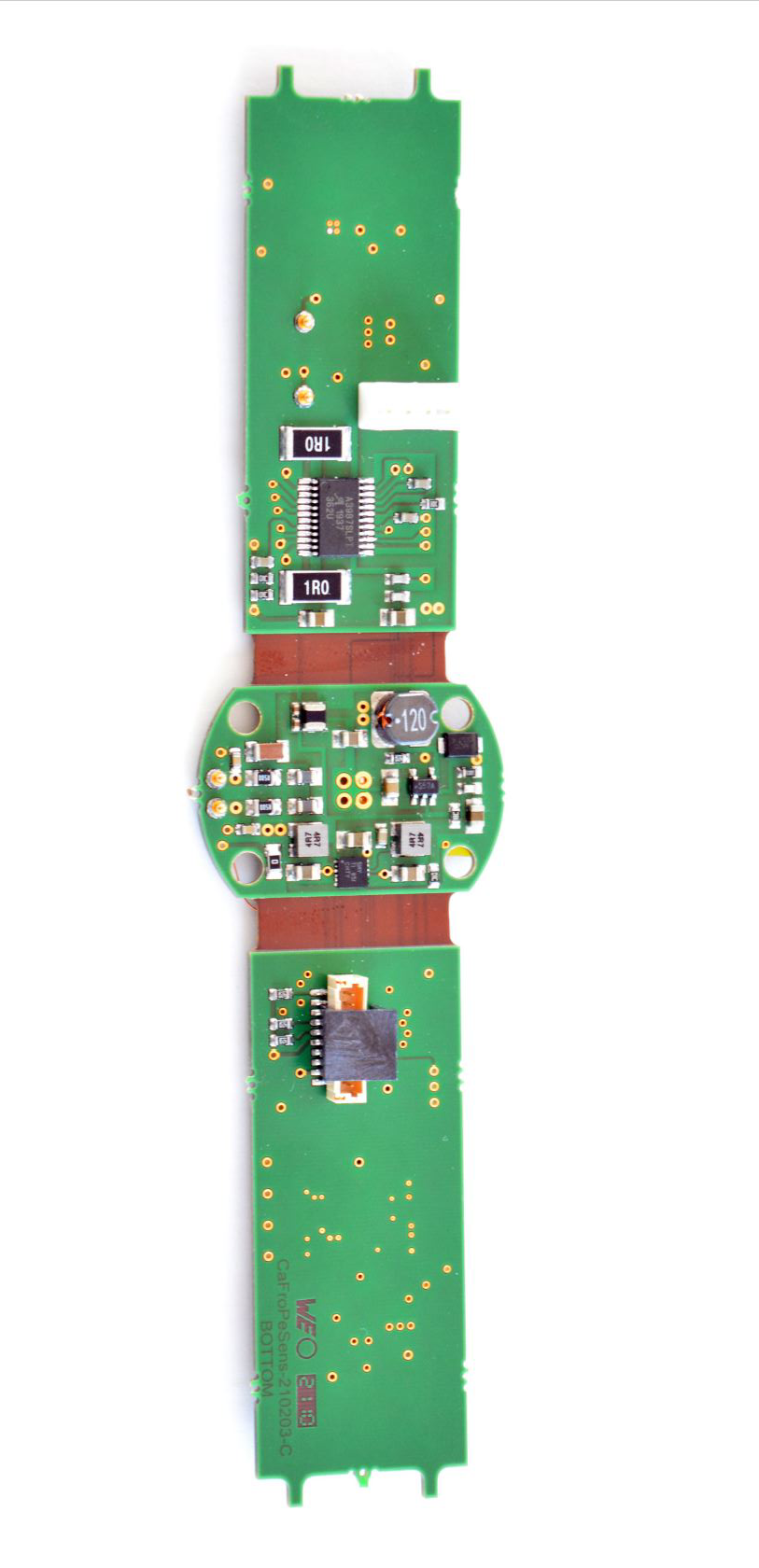

All scientific methods ultimately depend on suitable control and measuring electronics. In cooperation with research partners Gebrüder Heyl and SEBA Hydrometrie, a miniaturized and intelligent electronic solution was realized. An equally complex but fully integrated circuit board was developed. The project highlight is the functional integration of a miniaturized multi-channel potentiostat.

All measured values are communicated via a common protocol to a centralized electronics system. The multi-parameter unit (by SEBA Hydrometrie) coordinates the measuring operation and combines all relevant data. The software and hardware adaptation were completely realized during the project.

Status

Ongoing project 01/2019 — 12/2022

More information

Partner

The project is a joint initiative of Institute of Applied Research (IAF) of Karlsruhe University of Applied Sciences (HKA) , Gebrüder Heyl Analysentechnik GmbH & Co. KG, Hildesheim, SEBA Hydrometrie GmbH & Co. KG, Kaufbeuren and Fraunhofer-Institute for Chemical Technology ICT, based in Pfinztal (near Karlsruhe).

Project funding

The project is funded by the Federal Ministry of Education and Research (BMBF) under the funding reference 02WQ1483A-D and is supported as part of the measure „KMU-innovativ: Ressourceneffizienz und Klimaschutz“ in the application area „Nachhaltiges Wassermanagement“ unterstützt. The measure is part of the BMBF-program „Research for Sustainability“ (FONA³).