Motivation

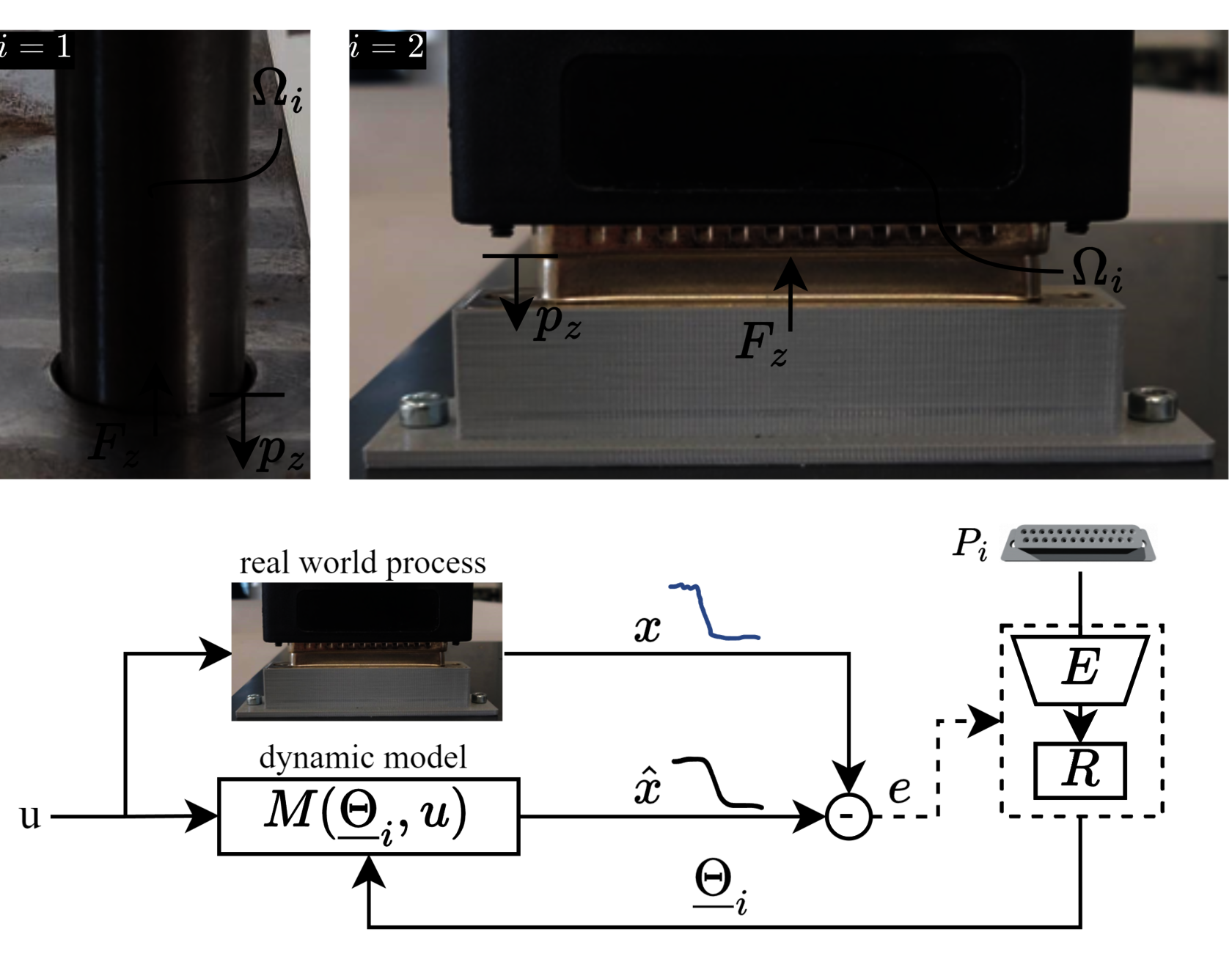

In the product creation process, a CAD assembly of the product to be produced is designed. Its sub-assemblies or components must be joined together in a certain way (plugged, clamped, pinned, etc.) as specified by the planning algorithm. A force control system is required for the assembly robot used so that the process forces can be maintained during joining. Traditionally, the control is parameterized once by an expert. For assembly lines where the product to be assembled does not change, this is sufficient, but also involves considerable costs. However, this procedure is uneconomical and time-consuming, particularly in the case of high product diversity with small quantities. Consequently, flexible parameterization of the automation line is absolutely essential here.

Overall goal

The aim is to automate the parameterization of robot systems by using prior knowledge from the product development process in order to achieve flexible adaptation to new tasks. In future, this will enable small and medium-sized enterprises to integrate intelligent and flexible production systems cost-effectively, even for small quantities.

Data from the production development process is used. For example, CAD data contains information about the geometry and material of the respective components. An AutoEncoder structure is pre-trained using geometric primitives from the same object category. Transfer learning tailored to the specific process is then made possible using just a small amount of real data.

Project funding

The PIPE project is funded by the Federal Ministry of Research, Technology and Space and the Ministry of Science, Research and the Arts as part of the federal-state program FH-Personal.