Motivation

Current studies show that productivity in the manufacturing industry can be increased by up to 50 percent through the use of artificial intelligence, lean production and digital innovations. This potential also applies to the machine tool industry and machining production. In practice, however, value-added functions based on AI, for example for optimizing cutting data or detecting tool wear, are still the exception.

There are many reasons for this. The machine landscape is highly heterogeneous, which leads to high complexity and process variability. As a result, existing approaches can hardly be scaled, meaning that only isolated solutions have been available to date. In addition, many processes require large volumes of data and very high data quality. Companies have to plan for considerable machine runtimes and deploy qualified personnel before a solution works reliably. In addition, many machines are not designed for the required data acquisition and would have to be retrofitted at great expense. Measuring systems such as static or dynamic dynamometers can account for up to 25 percent of the acquisition costs of a machine tool.

All these hurdles make the use of intelligent machine value-added functions in industry difficult, especially for small and medium-sized companies. This is precisely where the "PATTERN - Machining force estimation based on integrated machine tool data for intelligent machine value-added functions" project comes in.

Overall goal

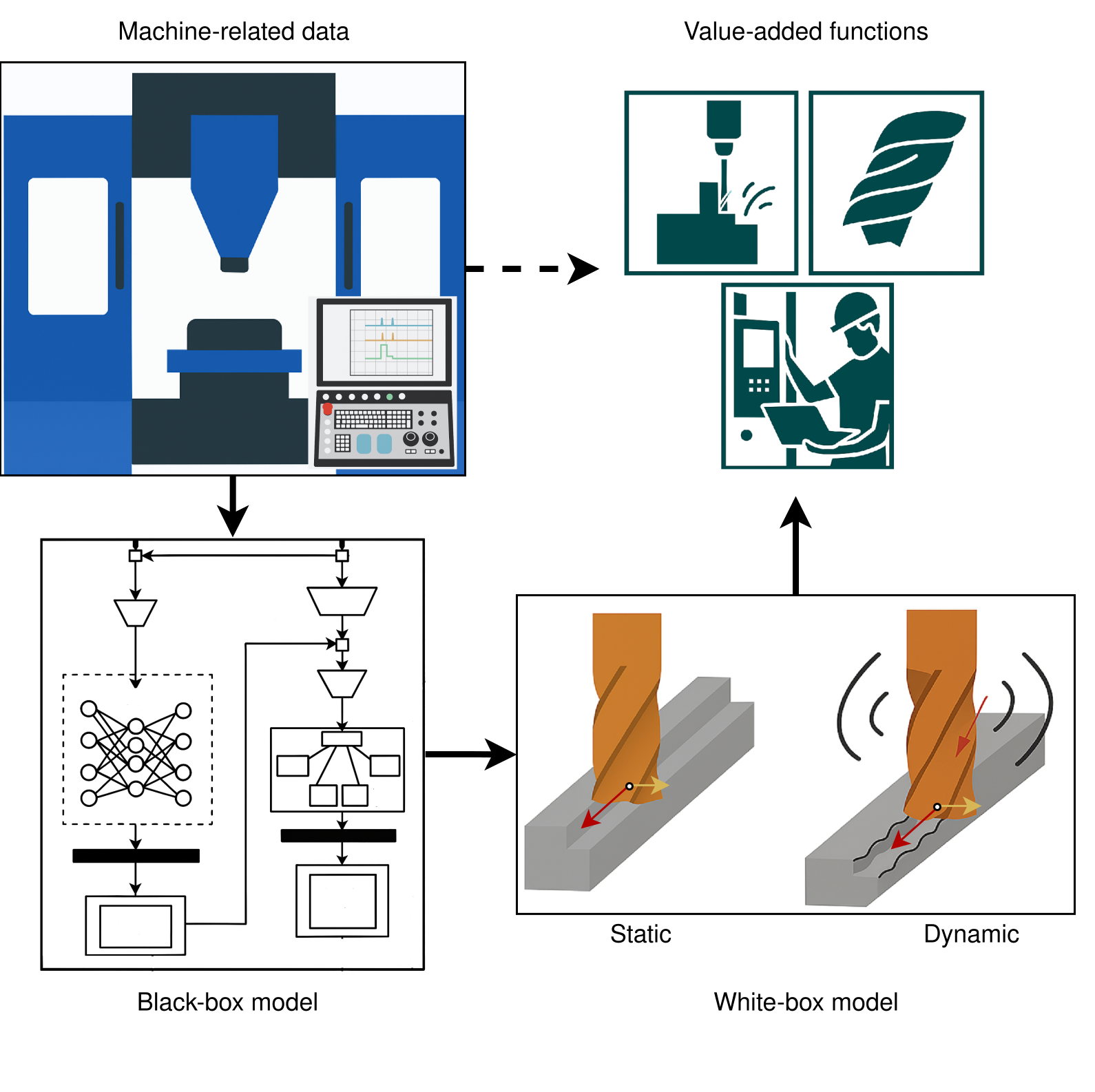

The research project is developing a hybrid approach for predicting milling forces. This combines physical models with data-driven methods and is based exclusively on data collected close to the machine. The aim is to significantly improve the data efficiency, generalizability and interpretability of value-added functions in machining production. This should simplify the application of AI in this industry and enable its widespread use, especially for small and medium-sized companies.

Methodology

As part of the project, CORE PATTERN is being developed as a hybrid model for estimating milling forces. These forces contain most of the process-relevant information and therefore form the basis for a precise description of milling processes. They are also the key to the development of value-added functions. A model that reliably predicts milling forces demonstrates a deep understanding of the process and can be flexibly transferred to different application scenarios.

However, as the estimation of cutting forces is influenced by a large number of process parameters, CORE PATTERN is divided into two modules. The first module processes machine-related data in a data-driven black box model and uses it to derive cutting and vibration coefficients. These values serve as input data for the second module, which is based on two physical white box models. While one calculates the static milling forces, the other determines the dynamic forces. In the end, both results are combined to map the real milling force as accurately as possible.

The performance of CORE PATTERN is verified by specific value-added functions. For example, the optimization of cutting data using the estimated milling forces is demonstrated, thereby demonstrating the practical benefits of the hybrid approach.

Industry partners ISG Industrielle Steuerungstechnik GmbH and Lorenz Hoffmann are contributing their experience to ensure that the methods developed are practical and feasible right from the start. Together, they have more than 75 years of expertise in machining and thus ensure a close link between research and industrial application.

Project funding

The PATTERN project is funded by the Ministry of Science, Research and the Arts as part of the "Innovative Projects/Cooperation Projects" program.