Miller-Lambda-1

Miller-Lambda-1

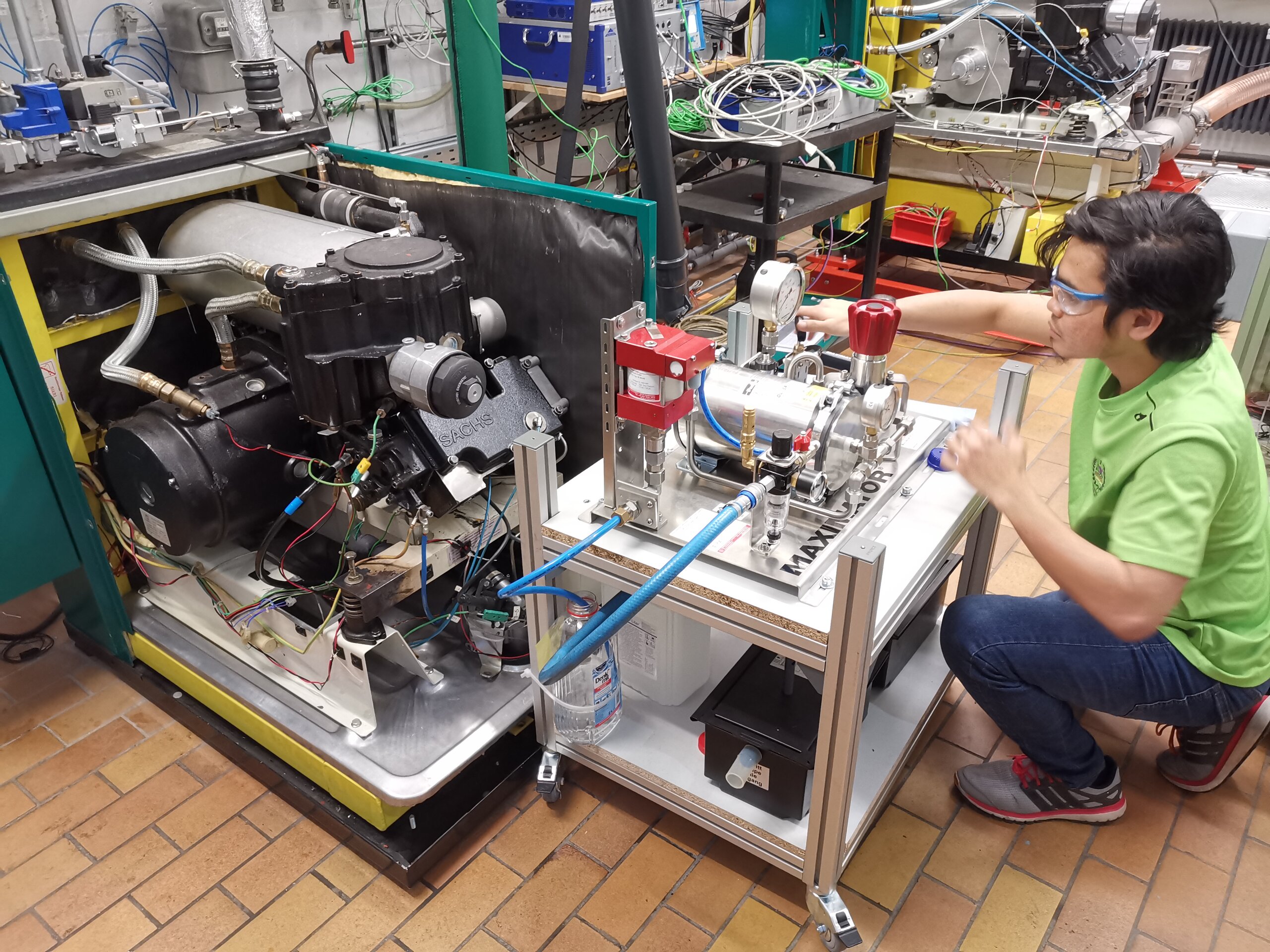

A stoichiometric combustion process with extended expansion via the valve train has been developed at GenLab in cooperation with SenerTec GmbH. The area of application focuses on gas-fired cogeneration plants in the small power range. The goal was to improve the trade-off between efficiency and NOx emissions so that future emission limits can be met while maintaining high plant economics.

In the first step, a comprehensive measurement of the test vehicle in stoichiometric operation and with a three-way catalytic converter was carried out under variation of various operating variables, with the aim of being able to evaluate the engine and emission behavior with a modified mixture strategy. On this basis, it was already possible to determine the target effective compression ratio and the target engine speed for the further tests. It also became apparent that, given sufficient exhaust gas temperature and the quality of the mixture control, almost complete conversion of the emissions can be achieved. With the help of the obtained database, an existing 1D engine process simulation model of the production lean-burn engine was next tuned to stoichiometric operation. Subsequently, a numerical study was conducted under va-riation of intake manifold length and intake valve closure to optimize gas dynamics and determine efficiency-enhancing timing. A total of one reference configuration corresponding to a conventional Otto timing and two Miller configurations were determined. The determined control times were then transferred to an existing multibody simulation model of the intake-side valve train, the mechanical load was verified, and the required grinding coordinates for manufacturing the cam profiles were derived.

In the final step, the designed configurations were examined experimentally and the target variant was determined. The targeted performance of the series engine could be set in knock-free operation with moderate EGR rates <10 % and efficiency-optimized center of gravity positions for all configurations. The highest efficiency was achieved with the latest Miller control time and the highest geometric compression ratio. Overall, a combustion process was developed in the project that forms the basis for subsequent series development and enables compliance with future NOx limits while simultaneously increasing efficiency and moderate system complexity.

Current information about the project

The project was completed in 2018.

Related publications

- Judith J, Neher D, Kettner M, Klaissle M, Schwarz D: High Efficiency by Miller Valve Timing and Stoichiometric Combustion for a Naturally Aspirated Single Cylinder Gas Engine. In: 25th Small Engine Technology Conference 2019. 25th Small Engine Technology Conference 2019 (SETC 2019) (Hiroshima, Japan, Nov. 19-21, 2019), Society of Automotive Engineers Japan 2019 (JSAE Paper 20199588), 17 p. (Electronic publication: https://saemobilus.sae.org/content/2019-32-0588/)

- Judith J, Neher D, Kettner M, Klaissle M, Schwarz D: Simulation-based development of a stoichiometric combustion process with Miller timing for a mixed-intake single-cylinder natural gas engine. In: WTZ Roßlau (Ed.): 11th Dessau Gas Engine Conference. 11th Dessau Gas Engine Conference (Dessau, April 11-12, 2019), Dessau: WTZ Roßlau 2019, 16 pp.

- Judith J, Neher D, Kettner M: Development and investigation of a combustion process with extended expansion via valve train for stationary gas engines. [Published 2019] ed., Osnabrück: DBU 2019, 41 pp. (Electronic publication: https://www.dbu.de/OPAC/ab/DBU-Abschlussbericht-AZ-32875_01-Hauptbericht_neu.pdf)

Project partners

Funding

Funding period

08.2016 – 07.2018