HydroGen

HydroGen

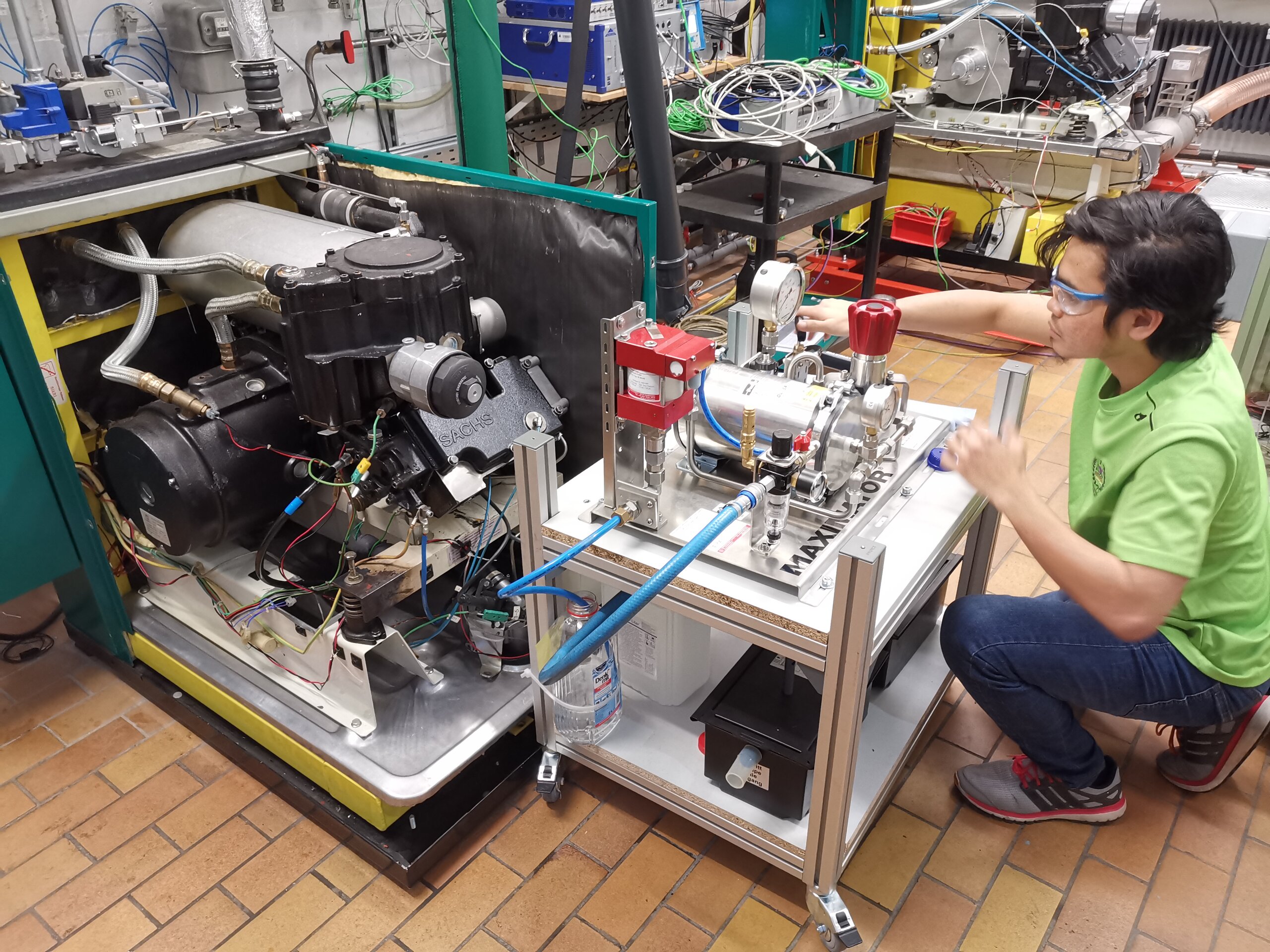

Development of a natural gas/hydrogen small CHP unit

The overall objective of the project is the design and development of a hydrogen-compatible, highly efficient engine concept for use in mini combined heat and power plants (CHP) based on a stationary natural gas single-cylinder engine of the latest technology. Against the background of increasing hydrogen contents in the natural gas grid due to power-to-gas, the planned CHP concept aims at the reconversion of hydrogen generated from surplus electricity in arbitrary concentrations. In this context, the envisaged motor concept is to function reliably and as efficiently as possible (efficiency-optimized combustion) with different fuels (natural gas with up to 100 % hydrogen content). Taking into account the high hydrogen knock sensitivity and the objective of operating the engine between pure natural gas operation, natural gas operation with variable hydrogen admixture and pure hydrogen operation without power reduction, the adaptation of the effective compression ratio and suitable charge dilution represent essential measures. The fundamentally stoichiometric operation of natural gas operation is to be maintained even with increasing H2 fuel gas fractions by controlled charge dilution with dried and low-CO2 exhaust gas (H2 combustion), thus realizing the oxymoron of "stoichiometric lean operation": thermodynamically efficiency-favorable material properties of lean operation with simultaneous stoichiometric combustion.

Current information about the project

The project Hydrogen is being worked on in a research network comprising several project partners from research and industry. The development process includes experimental and numerical investigations for the design of the hydrogen combustion process as well as the CHP plant. The experimental investigations take place at the Amberg-Weiden University of Applied Sciences, while the GenLab at the Karlsruhe University of Applied Sciences performs the numerical investigations. The numerical investigations include:

- 0D simulation (Cantera, AVL Fire): Ignition delay, flame speed

- 1D engine process simulation (AVL Boost): Timing, combustion process design

- 3D combustion and flow simulation (AVL Fire): Combustion chamber geometry

In all cases, chemical reaction mechanisms are used to describe combustion. With the help of the numerical results, on the one hand, fundamental relationships in the use of natural gas-hydrogen mixtures in small CHP units are to be obtained, as well as the combustion process to be designed. The method of the "digital twin" ensures the transferability of the results to the real test vehicle at the project partner's site in Amberg.

Students

Students have the permanent opportunity to participate in simulation projects as research assistants (Hiwi) or in the context of project (PA, F&E) and final theses (Bachelor, Master). Open topics can be found under student research or by direct contact with the responsible staff member.

Funding period

seit 2019

Last updated

26.02.2021