VEHICLE – Hybridisation of Lithium-Ion Batteries with Supercapacitor

The energy storage system in electric or plug-in hybrid vehicles today represents the weakest link in a vehicle's drive system with the disadvantages of cost, limited range, long charging time, etc. Therefore, the challenge for the automotive industry is to develop embedded energy storage systems. Innovative solutions must improve vehicle performance in terms of battery life and system size, in other words: reduce the total cost of ownership. Hybridisation of energy storage systems is being tested as a promising approach. In particular, the use of two complementary storage technologies, or more precisely, technologies with high energy density on the one hand and storage with high power density on the other. This hybridisation makes it possible to exploit the advantages of both storage systems and also offers a further degree of freedom with regard to the design of the storage sizes.

IEEM is developing an energy management system for an innovative drive train in electric vehicles as part of the European project VEHICLE

The VEHICLE project is being developed as part of the INTERREG V Upper Rhine programme and the Offensive Science initiative. It is co-financed by the Grand Est Region (France) and the Federal States of Baden-Württemberg and Rhineland-Palatinate (Germany) within the framework of this initiative. The acronym VEHICLE stands for "AdVanced li-ion battEry/supercapacitor HybrId energy storage system with synchronous reluctance maChine for eLEctric vehicle applications". The main objective is to optimise the Total Cost of Ownership (TCO) of an electric vehicle by improving the battery lifetime through a hybrid energy storage system (HESS) and the use of an advanced synchronous reluctance machine. This project aims to strengthen knowledge transfer, networking and cooperation between companies and universities.

Goals of the projects

Based on this idea, the concrete goals are as follows:

- Find the optimal technical combination of battery and electric machine so that electric vehicles achieve higher customer acceptance.

- Evaluate the influence of energy management strategies on the dimensioning and lifetime of a HESS.

- Development of intelligent energy management systems (EMS) based on predictive algorithms suitable for battery life prediction.

- Selecting and designing a compact power converter for HESS consisting of Li-ion batteries and supercapacitors.

- Development of an optimal control for synchronous reluctance machines to minimise the influence of current harmonics on battery lifetime.

- Development of a lightweight and scalable test setup for an electric powertrain based on a hybrid battery/supercapacitor storage approach and a synchronous reluctance machine.

- Development of a holistic model-based energy management and lifetime prediction for lithium-ion batteries for use in combination with supercapacitors.

- Refinement and validation of the developed battery model through programmed cycling and impedance tests in combination with other in situ methods.

- Development of dedicated test equipment for advanced battery diagnostics for cell ageing.

- Lifetime prediction of Li-ion batteries and their comparison in a hybrid and singular use.

Implementation

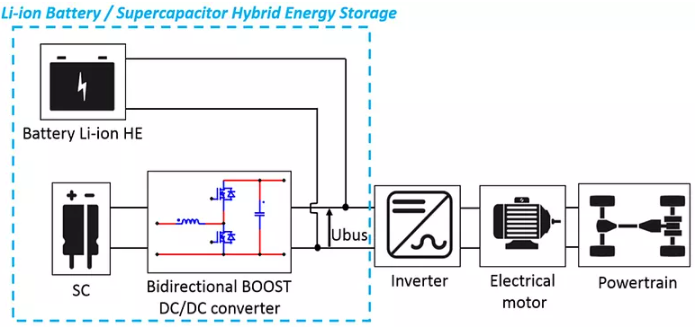

The proposed solution is based on the use of a HESS and combines the strengths of two complementary technologies in the form of specific energy and power density technologies as shown in the figure below. The storage system consists of Li-ion batteries and supercapacitors. A bidirectional DC/DC power converter is also necessary on the supercapacitor side to ensure power distribution as well as sensible operation of the synchronous reluctance machine for the drive train. The latter is usually also coupled with a DC/AC converter.

Key data

Karlsruhe

Institute of Energy Efficient Mobility (IEEM)

Moltkestr. 30

76133 Karlsruhe

Post >

Institute of Energy Efficient Mobility (IEEM)

Postfach 2440

76012 Karlsruhe