Microstructure - Diffusion

Modeling heat transport in porous structures - including under the influence of flows

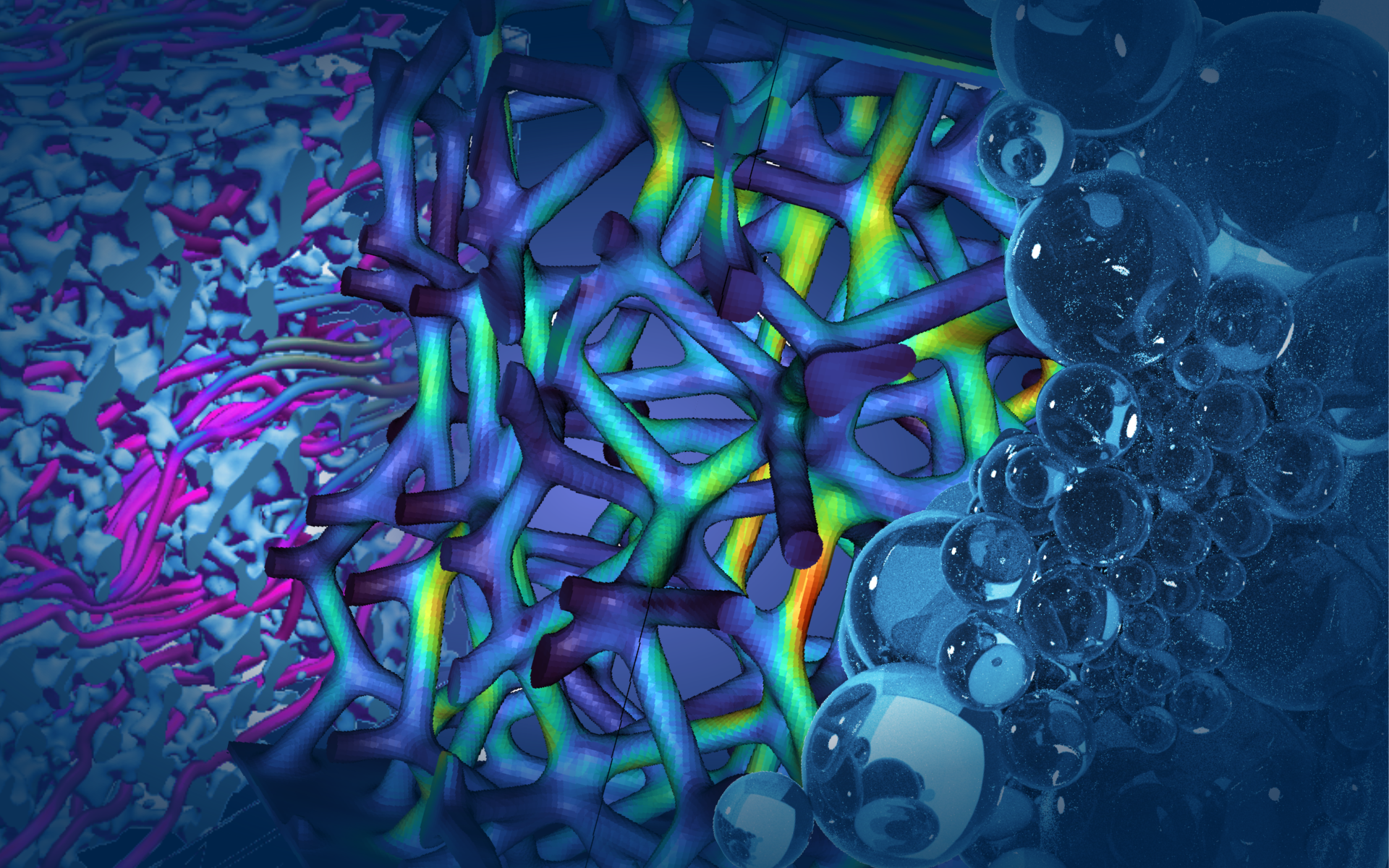

The research activities of the Microstructure - Diffusion group focus on the modeling of heat transport in porous structures, including under the influence of flows. The aim is to improve the efficiency of heat exchangers, heat collectors and heat accumulators depending on the microstructure and material properties. Phase transformation processes of the fluid medium are taken into account when modeling the process sequences. The research group develops optimal structures of the porous materials involved, for example the structure of a metal foam.

Most important research projects

Metal foams

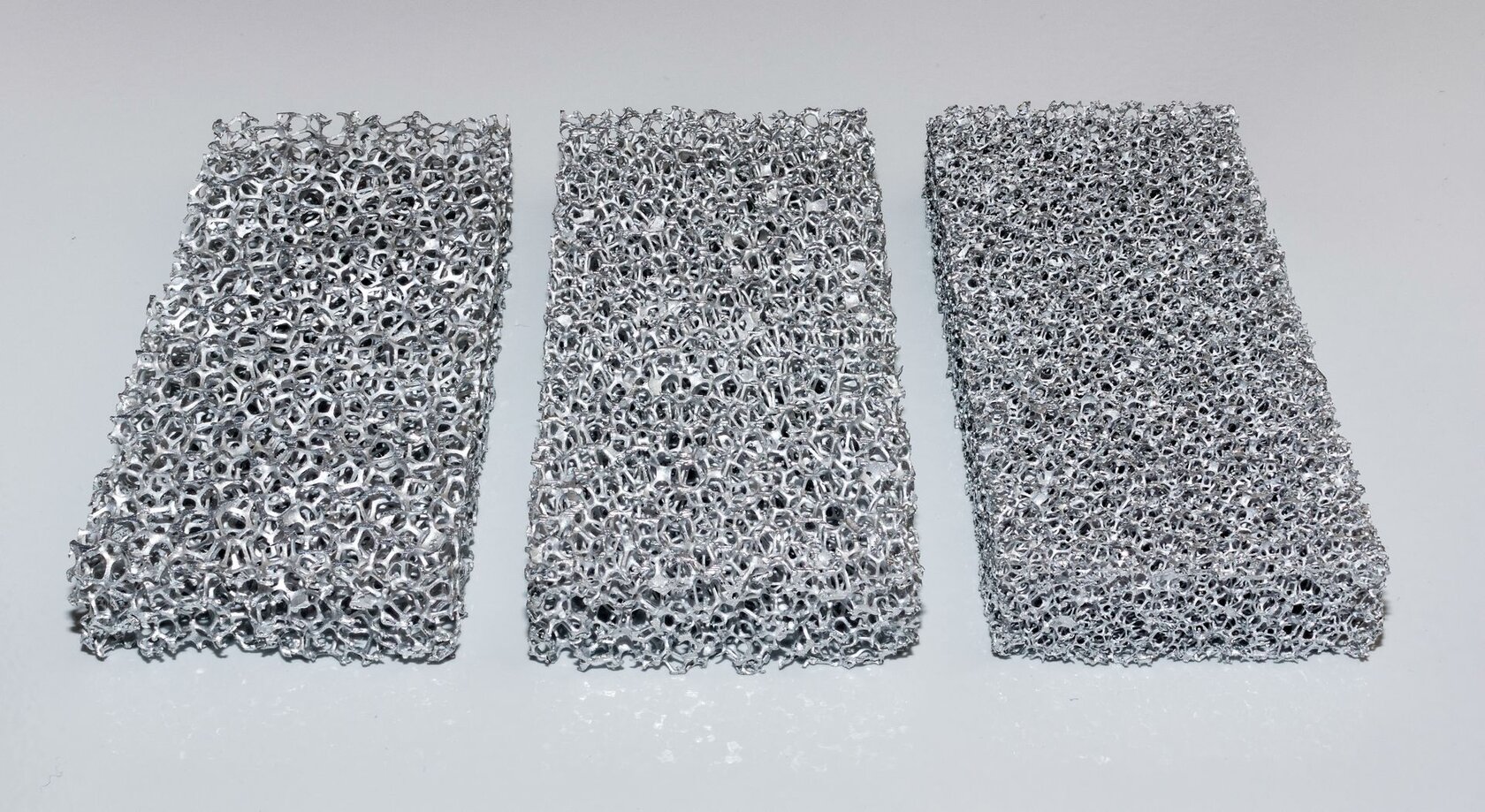

Metal foams are materials with excellent properties. They look like beer foams, only without beer and essentially without the walls between the individual bubbles. Only where three or more bubbles meet is there still material. These so-called webs form an irregular, solid network that still largely retains many of the properties of the base material - metal: Thermal conductivity, stability and electrical conductivity. In addition, they offer much more: the lightness, the lower basic material requirement and - in particular - the large surface area compared to the volume. For example, heat can be exchanged with the air around the bars via this surface area. This property, combined with the good thermal conductivity of metal, makes metal foams popular objects of our research within the KIT program Energy Efficiency, Materials and Resources.

Solar thermal energy

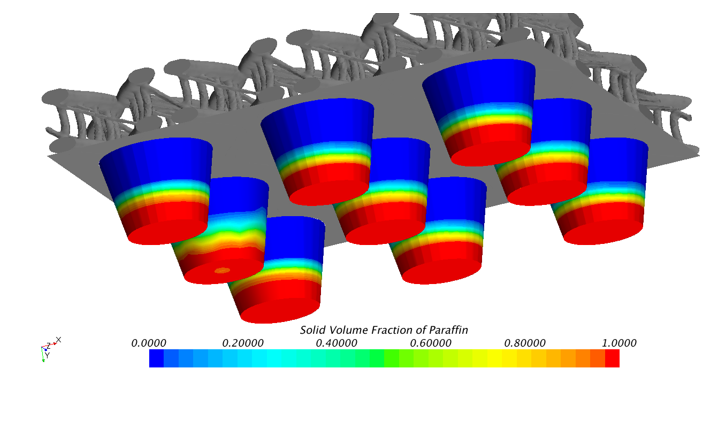

Solar energy can be absorbed particularly well by black objects. For example, the skin of a polar bear is black so that it can extract as much energy as possible from the sunlight at the North Pole. The white fur, which lets the sunlight through, serves to insulate its own body heat. Based on this principle, heat collectors made from textile spacer fabrics are being developed in the solar thermal energy project - together with our project partner, the Institute of Textile Technology and Process Engineering Denkendorf (→ www.uni-stuttgart.de/forschung/orp/inst_profile/we/itv.html). In addition to energy generation, its storage naturally also plays a major role. In the second stage of the project, new storage systems are being tested: Small thimble-sized buckets filled with kerosene, for example, which are to be placed directly under the textile collector. Kerosene stores latent heat when it melts and releases it again when it solidifies. At CMS, we test various systems using computer simulations and make suggestions for improving their geometry.

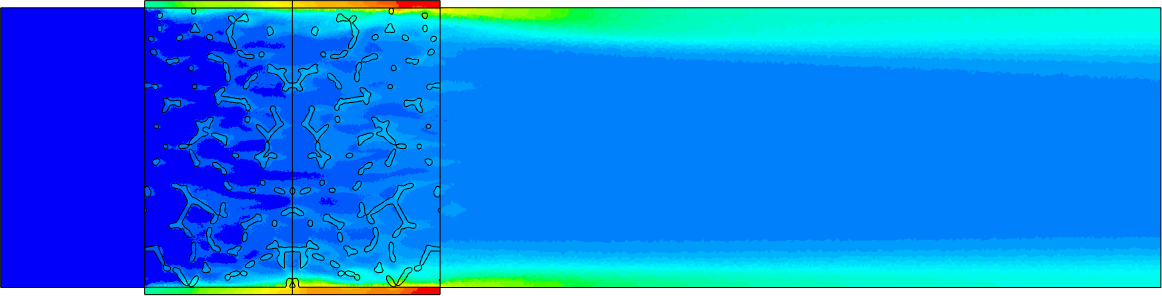

Porous water pipes

Using energy resources as efficiently as possible is an important challenge for the future. In materials science, this results in the search for efficient, inexpensive and practical materials for heat conduction and storage. Metallic foams represent a promising approach to solving problems of energy transfer and storage, as they have both the property of permeability for fluids and a large surface area. This enables more efficient heating of liquids and other possible fillings. The aim here is to achieve the greatest possible heat transfer with the lowest possible pressure loss. These foams are first produced using computer simulations in which the material is tested for various conditions, such as temperature or pressure changes, and the influence of different pore sizes. A 3D printer is then used to produce a model for the investment casting of the optimum foam.

Metal foams are used, for example, in the design of water pipes that transfer their energy to the water more efficiently.

InSeL: Innovative foam structures for efficient lightweight construction

The research project InSeL (Innovative Foam Structures for Efficient Lightweight Construction) is a research initiative for lightweight construction research in Baden-Württemberg, consisting of an association of various universities, non-university institutions and companies in which the IAM of the KIT is involved. It includes joint research, but also the communication of research results to companies and the networking of InSeL members for further research projects. The focus is on three aspects:

Innovation aspect:

Due to ever-advancing technology, porous structures are highly sought-after materials, but their development is associated with a number of challenges, such as the development of composites.

Economic aspect:

The InSeL project aims to enable the economic exploitation of porous materials that have not yet been sufficiently utilized. This will increase the competitiveness of medium-sized companies in particular.

Communication aspect:

This aspect includes the communication of knowledge to companies. The interdisciplinary approach is also intended to strengthen communication between researchers.

Our sub-project:

Here at the MMS, we are participating in this project through computer simulations in the field of polymer foams, which serve as preforms in the casting of particularly fine-pored and monodisperse metal foams.

Popular science lectures by Dr. Anastasia August

Science Slam

Metal foam (part 1): Youtube

Metal foam (part 2): Youtube

Thermal conductivity: Youtube

Fog catcher (part 1): Youtube

Fog catcher (part 2): Youtube

Polar bear (part 1): Youtube

Polar Bear (Part 2): Youtube

Talking Science: Karlsruhe-Blog

Famelab: clickit-magazin

Famelab

Metal foam and kerosene: Youtube

Steadiness: Youtube

Polar bear: Feeds video (Uni-Erlangen)